金属顶刊双语导读丨Acta Mater. Vol.204,1 Fed. 2021

2021-03-28 来源:Goal Science

本期包含金属材料领域论文17篇,涵盖了镍合金、不锈钢、高熵合金、复合材料等,国内科研单位包括香港科技大学、天津大学等(通讯作者单位)。

Vol. 204 目录

1. On the Localization of Plastic Strain in Microtextured Regions of Ti-6Al-4V

Ti-6Al-4V微织构区的塑性应变局域化研究

2. Investigating the compressive strength and strain localization of nanotwinned nickel alloys

纳米孪晶镍合金的抗压强度和应变集中研究

3. Correlation of Measured Load-Displacement Curves in Small Punch Tests with Tensile Stress-Strain Curves

小冲孔试验载荷-位移曲线与拉伸应力-应变曲线的关联

4. Analysis of shape, orientation and interface properties of Mo2C precipitates in Fe using ab-initio and finite element method calculations

Fe中Mo2C析出相形状、位向和界面性能的第一性原理和有限元研究

5. Reducing hot tearing by grain boundary segregation engineering in additive manufacturing: example of an AlxCoCrFeNi high-entropy alloy

以AlxCoCrFeNi高熵合金为例说明晶界偏聚在降低增材制造热裂方面的应用

6. Effects of temperature on mechanical properties and deformation mechanisms of the equiatomic CrFeNi medium-entropy alloy

温度对等原子比CrFeNi中熵合金力学性能和变形机制的影响

7. Fusion bonding of copper and silicon at -70℃ by electrochemistry

铜和硅在-70℃下的电化学熔合

8. Phase-field simulations of grain boundary grooving under diffusive-convective conditions

扩散-对流条件下晶界沟槽的相场模拟

9. In-plane low thermal expansion of NiTi via controlled cross rolling

通过交叉轧制方法实现NiTi合金的面内低热膨胀

10. Atomic-scale Investigation of Liquid-Metal-Embrittlement Crack-path: Revealing Mechanism and Role of Grain Boundary Chemistry

晶界化学成分对液态金属脆化机制影响的原子尺度研究

11. A micromechanical analysis of intergranular stress corrosion cracking of an irradiated austenitic stainless steel

辐照诱导奥氏体不锈钢晶间应力腐蚀开裂的微观力学分析研究

12. Revealing the strengthening and toughening mechanisms of Al-CuO composite fabricated via in-situ solid-state reaction

原位固相反应制备Al-CuO复合材料的强化增韧机理研究

13. Resolving the porosity-unmelted inclusion dilemma during in-situ alloying of Ti34Nb via laser powder bed fusion

Ti34Nb合金原位激光粉末熔炼过程中气孔-夹杂问题的解决方案

14. Accommodation and formation of {-1012} twins in Mg-Y alloys

Mg-Y合金中{-1012}孪晶的调节与形成

15. Ultra-efficient reconstruction of 3D microstructure and distribution of properties of random heterogeneous materials containing multiple phases

随机非均质多相材料三维组织和性能的超快速重构

16. Characterization of ductile phase toughening mechanisms in a hot-rolled tungsten heavy alloy

热轧钨重合金韧性相增韧机制的表征研究

17. Ultra-high strength and plasticity mediated by partial dislocations and defect networks: Part II: Layer thickness effect

分位错和缺陷网络致材料超高强度和塑性中的层厚效应

ACTA

Vol. 204,1 Fed. 2021, 116492

1. On the Localization of Plastic Strain in Microtextured Regions of Ti-6Al-4V

Ti-6Al-4V微织构区的塑性应变局域化研究

Jonathan Cappola✉, Jean-Charles Stinville, Marie-Agathe Charpagne, Patrick G. Callahan, McLean P. Echlin, Tresa M. Pollock, Adam Pilchak, Matthew Kasemer

J. Cappola:jgcappola@crimson.ua.edu

https://doi.org/10.1016/j.actamat.2020.116492

摘要

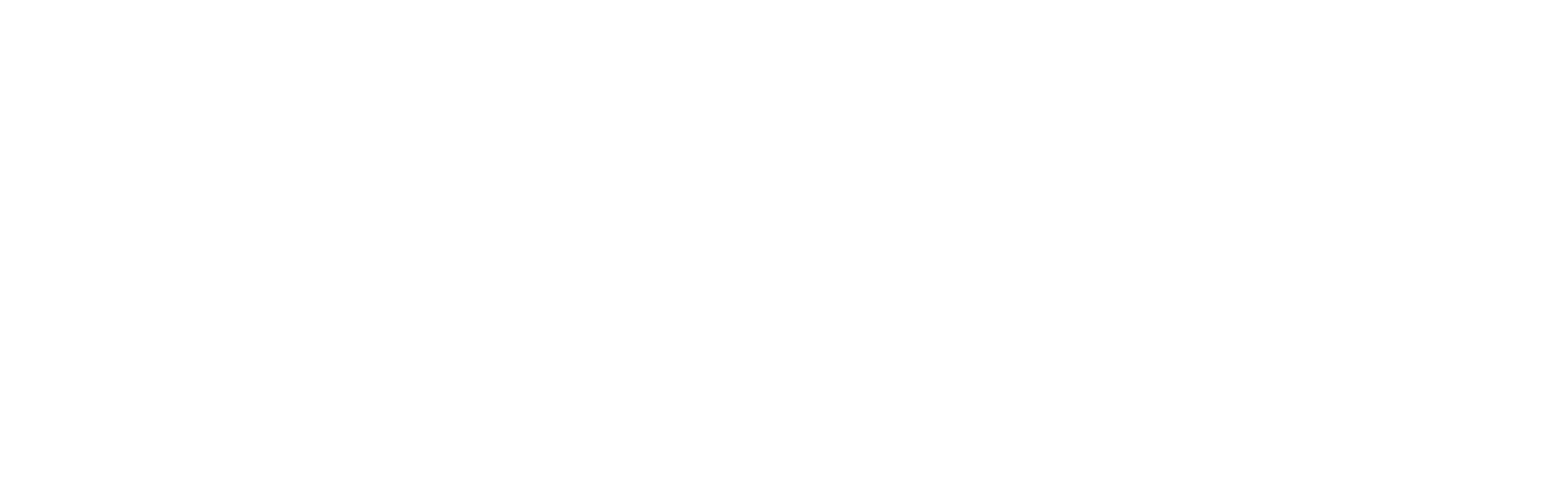

Ti-6Al-4V通常呈晶粒尺寸约10µm - 15µm的α相等轴晶组织。根据不同的加工方式,这些小晶粒可能会聚集成具有相似晶体取向的毫米级区域。这些所谓的微织构区域不利于材料的准静态和疲劳性能。它们促进长程应变集中和疲劳早期裂纹形核,使得塑性应变穿过晶界,终止于微织构区域边界,降低材料强度和塑性。此外,微织构区域内的小角晶界对裂纹扩展的阻力很小,因此这些区域内的裂纹扩展速率也相应增加。尽管目前关于微织构区域对材料宏观性能的影响已有大量研究,但目前对于微织构区域仍缺乏明确定义。为此,我们通过计算模拟研究了微织构强度和特征结构对材料应变集中的影响。在模拟过程中,我们对微织构强度和平均取向进行了参数化表征。结果表明,应变集中一方面是由于微织构区域内的集中取向,另一方面也受到邻近区域微织构强度的影响。在此基础处之上,我们基于Ti-6Al-4V样品晶内应变的高分辨实验结果对模拟结果进行了进一步讨论。

ACTA

Vol. 204,1 Fed. 2021, 116507

2. Investigating the compressive strength and strain localization of nanotwinned nickel alloys

纳米孪晶镍合金的抗压强度和应变集中研究

Gianna M. Valentino, Sisi Xiang, Luoning Ma, Kelvin Y. Xie, Mo-Rigen He, Warren C. Oliver, George M. Pharr, Jessica A. Krogstad, Timothy P. Weihs, Kevin J. Hemker✉

K.J. Hemker:hemker@jhu.edu

https://doi.org/10.1016/j.actamat.2020.116507

摘要

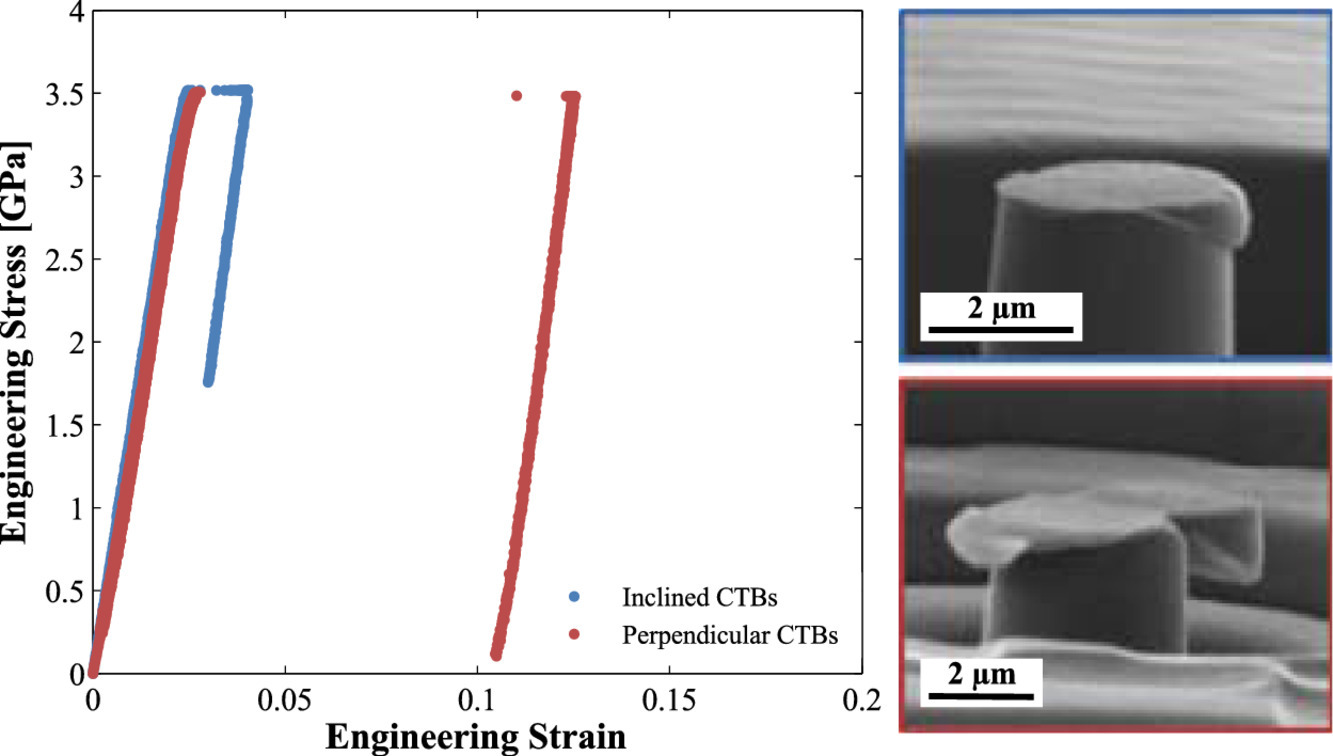

溅射沉积的Ni-Mo-W薄膜由于在沉积过程中形成细小的孪晶而具备一系列优异性能。此前,这种材料仅在拉伸状态被进行过表征,而在本研究中,我们对纳米孪晶Ni84Mo11W5进行了原位微柱压缩实验和表征,从而研究其压缩响应和对应的变形机制。微柱在抗压强度达到3-3.5 GPa时出现Hookean效应,非线性塑性流变表现为离散的应变增加和高度集中的剪切带。塑性变形主要集中在微柱顶部,而主体几乎不受影响。研究表明,在足够高的应力下,剪切带被触发,导致强烈和高度集中的塑性变形,使得形变剪切带内形成不含孪晶的纳米晶结构。而邻近剪切带的区域则不受影响。材料中缺乏脱孪和位错滑移机制,这一点令人意外,这与纳米孪晶Cu-Al中的观测结果截然相反。对Ni-Mo-W微柱的观察表明,超细孪晶导致了一种独特的塑性机制,材料抗压强度取决于剪切带的形成而不是位错滑移的激活。综上所述,纳米孪晶Ni-Mo-W的塑性机制十分独特,且其剪切带形成的详细机制仍有待进一步研究。

ACTA

Vol. 204,1 Fed. 2021, 116501

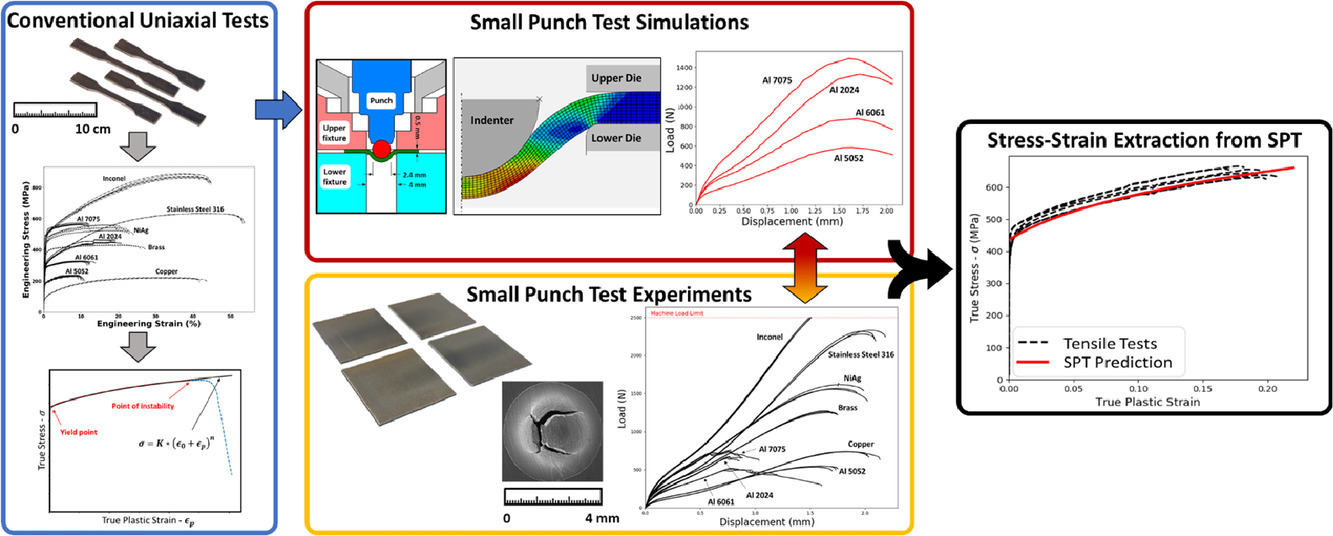

3. Correlation of Measured Load-Displacement Curves in Small Punch Tests with Tensile Stress-Strain Curves

小冲孔试验载荷-位移曲线与拉伸应力-应变曲线的关联

Nicolas Leclerc, Ali Khosravani, Sepideh Hashemi, Daniel B. Miracle, Surya R. Kalidindi✉

S.R. Kalidindi:surya.kalidindi@me.gatech.edu

https://doi.org/10.1016/j.actamat.2020.116501

摘要

小尺寸冲压试验(SPT)在评估高通量金属材料械响应方面具有重大应用价值。然而,它的应用目前主要局限于塑性材料屈服强度和抗拉强度等性能的评估。本研究中,我们首次提出了基于实测SPT荷载-位移曲线估计材料单轴应力-应变的方法。该方法是通过建立SPT测量结果和相应有限元(FE)模拟之间的联系实现的。在这一过程中,我们把单轴应力-应变响应作为有限元模拟的输入参数。研究表明,成功建立SPT和FE之间联系后,对于一未知试样,即可基于材料的SPT载荷-位移曲线反向推断出其单轴应力-应变响应。

ACTA

Vol. 204,1 Fed. 2021, 116478

4. Analysis of shape, orientation and interface properties of Mo2C precipitates in Fe using ab-initio and finite element method calculations

Fe中Mo2C析出相形状、位向和界面性能的第一性原理和有限元研究

Silvia Leitner, Daniel Scheiber✉, Thomas Dengg, Jürgen Spitaler, Thomas Antretter, Werner Ecker

D. Scheiber:daniel.scheiber@mcl.at

https://doi.org/10.1016/j.actamat.2020.11.020

摘要

我们通过密度泛函理论和有限元模拟相结合的对钢中的常见二次析出Mo2C及其与Fe基体的界面进行了研究。我们确定了Mo2C和Fe的弹性性能随温度的变化规律,并对碳化物与基体的不同界面进行了表征。我们将推导的弹性特性和界面能量为输入,通过有限元模拟,评估了弹性和蠕变对能量的贡献。通过结合原子尺度和微观尺度的结果模拟,我们可以较好地解释实验报道的析出物针状形貌。对于一个选定的界面,我们使用密度泛函理论确定了其全弹性性能,结果与Grimsditch-Nizzoli模型吻合良好。综上所述,我们的研究表明,通过密度泛函理论和有限元相结合的方法,可以很好地表征和理解析出相的微观力学响应。

ACTA

Vol. 204,1 Fed. 2021, 116505

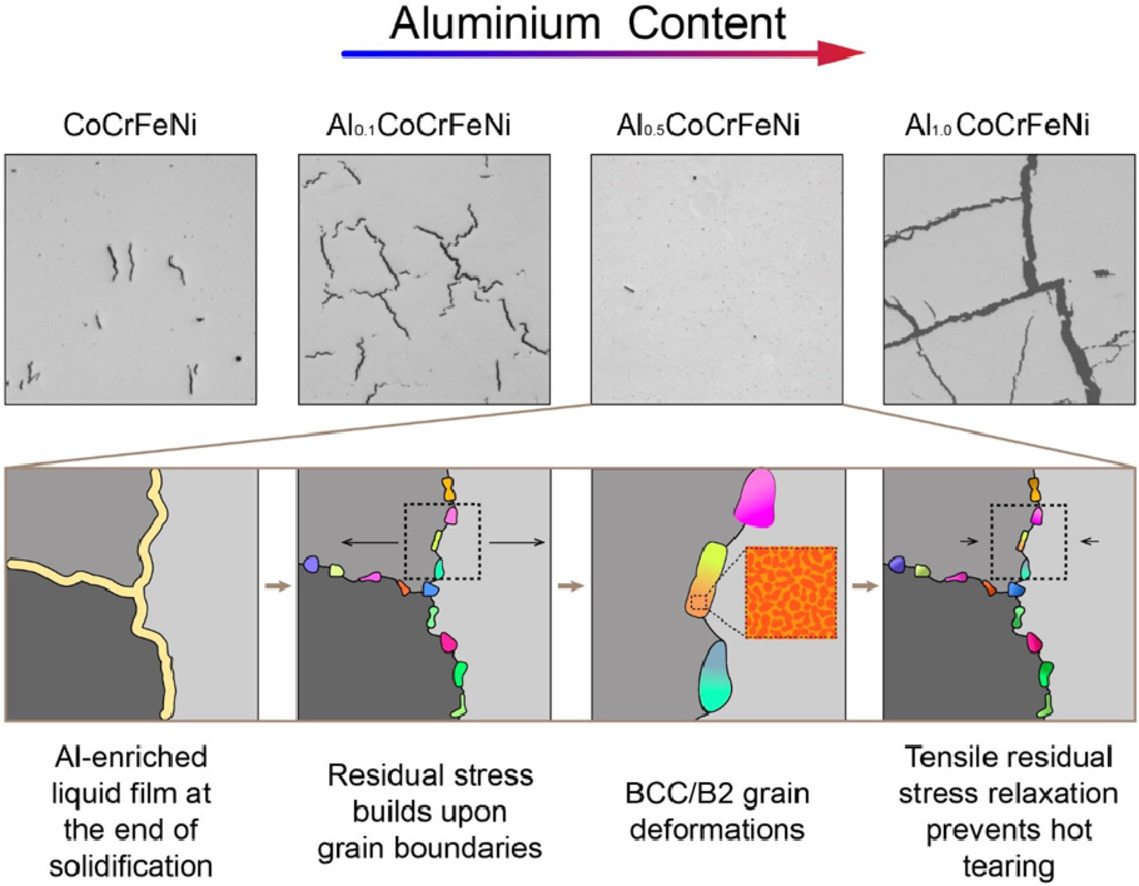

5. Reducing hot tearing by grain boundary segregation engineering in additive manufacturing: example of an AlxCoCrFeNi high-entropy alloy

以AlxCoCrFeNi高熵合金为例说明晶界偏聚在降低增材制造热裂方面的应用

Zhongji Sun✉, Xipeng Tan✉, Chengcheng Wang, Marion Descoins, Dominique Mangelinckc , Shu Beng Tor, Eric A. Jägle, Stefan Zaefferer, Dierk Raabe

Z. Sun:z.sun@mpie.de

X. Tan:xptan@ntu.edu.sg, xptan1985@ gmail.com

https://doi.org/10.1016/j.actamat.2020.116505

摘要

热裂是目前合金增材制造面临的难点之一。与以往研究中提出的减少凝固范围或引入晶粒细化的思路不同,在本文中,我们提出了新的方法,利用偏析改变枝晶和晶界处的残余应力,从而防止热裂的。我们将Al原位固溶进了一种易热裂的高熵合金CoCrFeNi。我们发现,在一定的成分范围内,如Al0.5CoCrFeNi,热裂现象显著减少。在这种成分的合金凝固过程中,Al首先从FCC相初生枝晶中被排出并偏析到枝晶间区域。随后,在这些富Al区域发生调幅分解,形成B2 NiAl 有序相和BCC Cr无序相。由于B2/BCC相具有较高的摩尔体积和较低的同源温度,因此固有残余应变被释放,在CoCrFeNi中最大为0.006拉伸应变,而在Al0.5CoCrFeNi中则转变为~0.001的压缩应变。我们认为利用现有的热/动力学数据库,这种晶界偏析方法可以为系统解决金属及合金增材制造中的热裂问题提供一种新的思路。

ACTA

Vol. 204,1 Fed. 2021, 116470

6. Effects of temperature on mechanical properties and deformation mechanisms of the equiatomic CrFeNi medium-entropy alloy

温度对等原子比CrFeNi中熵合金力学性能和变形机制的影响

Mike Schneider✉, Guillaume Laplanche

M. Schneider:mike.schneider@rub.de.

https://doi.org/10.1016/j.actamat.2020.11.012

摘要

我们对一种等原子比CrFeNi中熵合金(MEA)进行了研究,通过研究这种合金,可以更好地帮助我们理解和研发奥氏体不锈钢和铁基高温合金。研究表明,CrFeNi可在~1223 K以上形成稳定的面心立方(FCC)固溶体。在此基础上,我们通过冷加工和1273 K ~ 1473 K再结晶,得到了具有不同晶粒尺寸的合金材料。我们通过在293 K进行压缩试验,研究了晶界的强化作用 (测得Hall-Petch公式中的斜率为966 MPaµm1/2)。将这一贡献从整体强度中减去后,我们推测本征单轴晶格强度约为80 MPa。我们通过在77 K ~ 873 K进行压缩和拉伸试验,研究了温度对材料力学性能和变形机制的影响。研究表明,材料的延展性、屈服强度和抗拉强度都随温度的降低而增加。为了揭示粗晶(160µm)CrFeNi的变形机制,我们将其在77 K和293 K不同应变条件下进行了拉伸试验和透射电镜表征,发现在所有情况下,低应变时变形均通过位错滑移发生,而在165 MPa的临界剪切应力以上则还会发生孪晶。该临界剪切应力值与温度基本无关,且与Kibey模型预测的孪晶形核应力180 MPa吻合良好。此外,由于FCC金属/合金的孪晶成核势垒(即不稳定孪晶层错能)随温度变化不大,因此该值与温度基本无关,这一点也与Kibey模型一致。

ACTA

Vol. 204, 1 Fed. 2021, 116486

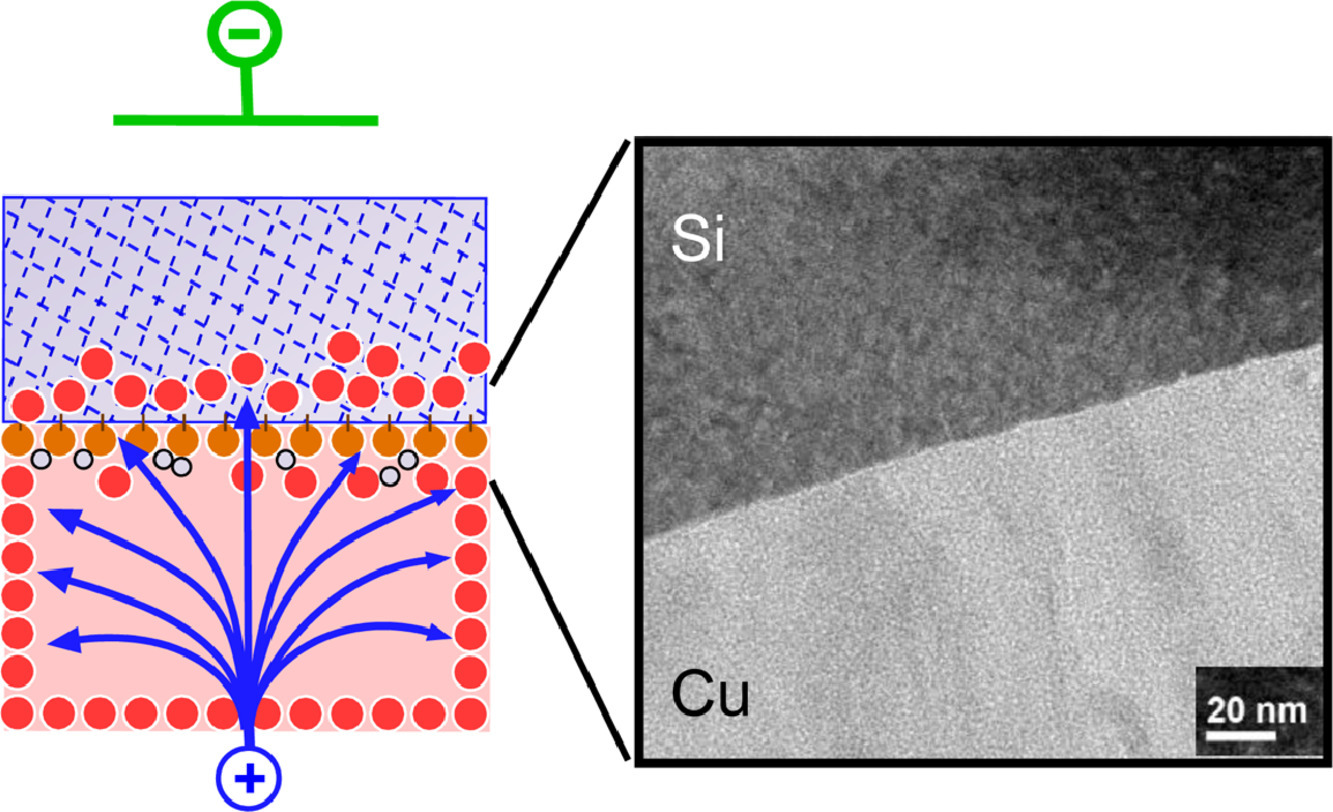

7. Fusion bonding of copper and silicon at -70℃ by electrochemistry

铜和硅在-70℃下的电化学熔合

Po-Yen Chien, Lin Cheng, Cheng-Ying Liu, Jhong-En Li, Benjamin Tien-Hsi Lee✉

B.T.-H. Lee:benlee@ncu.edu.tw

https://doi.org/10.1016/j.actamat.2020.116486

摘要

圆片焊接工艺通常需要高温促进原子相互扩散,从而实现两个表面的熔合。然而,我们发现,铜和硅的熔合可以在干冰(-20°C)甚至液氮(-70°C)冷却的极低温电化学条件下发生。研究表明,电能可以代替半导体加工过程中需使用的热能。虽然铜表面不利于自发键合,键合现象仍反复发生。值得注意的是,Cu/Si的结合强度非常高。即使在连接界面处强行插入剃须刀,铜层也会因粘附在硅上而从铜基体上被剥离。二次离子质谱(SIMS)分析表明,键合是由表面铜原子和硅原子之间的纳米级相互扩散引起的。对此,我们提出了一种可能的机制,即空穴在电场下被驱动至Cu/Si的键合界面,使Cu原子带正电荷形成阳离子。电场不断驱动Cu阳离子与硅原子上悬垂的键结合形成Si-Cu键。较晚到达的Cu阳离子可以通过键合界面并迅速扩散到硅原子间隙中。在-70°C下通过电化学辅助互扩散就能进行键合,这对工程应用具有深远意义。

ACTA

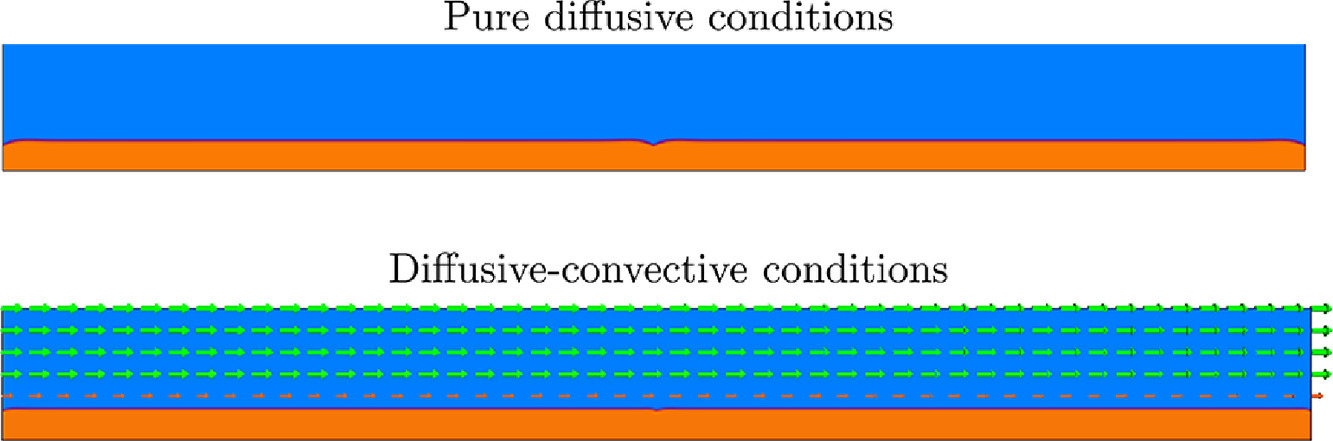

Vol. 204, 1 Fed. 2021, 116497

8. Phase-field simulations of grain boundary grooving under diffusive-convective conditions

扩散-对流条件下晶界沟槽的相场模拟

V. Pavan Laxmipathy✉, Fei Wang, Michael Selzer, Britta Nestler

V.P. Laxmipathy:pavan.veluvali2@kit.edu

https://doi.org/10.1016/j.actamat.2020.116497

摘要

晶界是凝固界面上可能的形貌不稳定位置,对铸态合金的组织性能有重要影响。在本研究中,我们采用了多相场模型来解释液相中对流和体积扩散协同作用下的晶界沟槽现象。在纯扩散条件下,我们首先通过描述和比较穿过晶界的对称沟槽和Mullins沟槽的形成,确立了相场模型的基准。随后我们在对流机制存在的条件下,系统地描述了沟槽的不对称性随对流速度增加而增加的现象。我们发现,在扩散-对流状态下,沟槽的动力学和形成机制被大幅修正。这项二维模拟,一方面加深了我们对晶界沟槽形成机制的理解,另一方面填补了此前实验观察和理论模拟之间的空白。此外,我们详细讨论了比表面能对沟槽深度和形貌的影响。以上晶界特征的模拟对于理解和调控纳米晶薄膜的制备具有重要意义。

ACTA

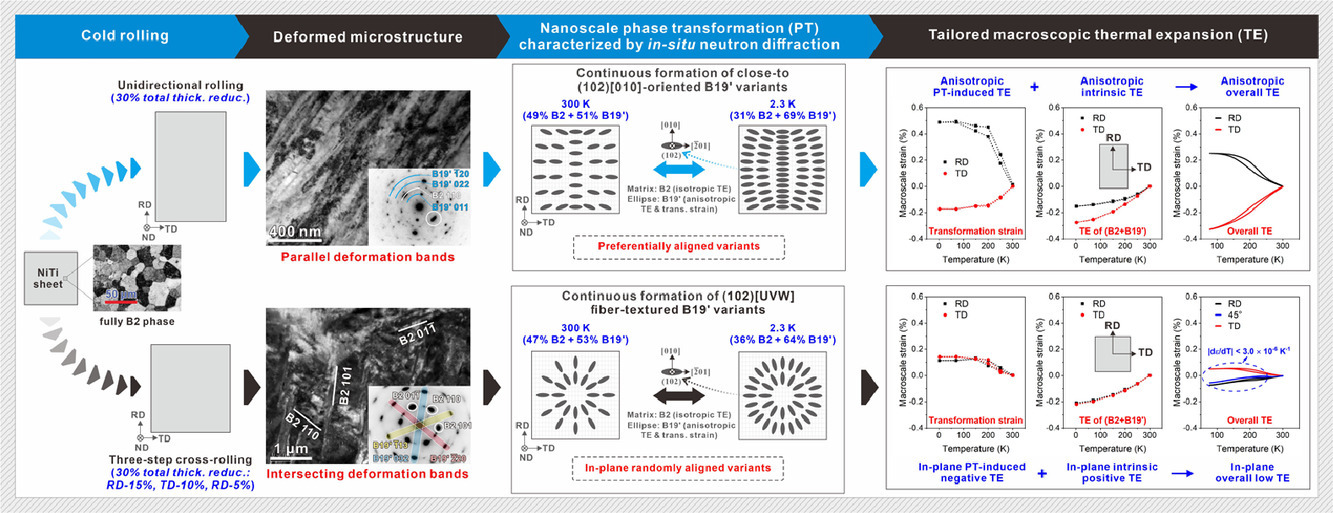

Vol. 204, 1 Fed. 2021, 116506

9. In-plane low thermal expansion of NiTi via controlled cross rolling

通过交叉轧制方法实现NiTi合金的面内低热膨胀

Qiao Li, Zhongzheng Deng, Yusuke Onuki, Wei Wang, Laifeng Li✉, Qingping Sun✉

L. Li:laifengli@mail.ipc.ac.cn (北京理化技术研究所)

Q. Sun:meqpsun@ust.hk(香港科技大学)

https://doi.org/10.1016/j.actamat.2020.116506

摘要

经单向轧制后的形状记忆合金(SMA)板材在较宽的温度范围内表现出较低的宏观热膨胀(TE),但仅限某一特定方向。在此,我们采用交叉轧制(CroR)成功在多晶NiTi板材中实现了面内低热膨胀。研究表明,经过RD-15%、TD-10%和RD-5%的三步交叉轧制制备得到的NiTi板材可以在223 K的温度范围内,实现近零面内膨胀(热膨胀系数-2.7 × 10−6 K−1 ~ 3.0 × 10−6 K−1)。这一面内热膨胀系数比单向轧制NiTi板材小一个数量级,与商业化的FeNi因瓦合金(热膨胀系数~2.0 × 10−6 K−1)相当。我们通过2.3 K ~ 300K进行的原位中子衍射实验结合混合规则模型,对这种面内低膨胀系数的物理成因进行了讨论。我们发现在交叉轧制纳米结构NiTi的冷却(加热)过程中, B2和B19’织构的正面内热膨胀被连续形成(消失)的{102}< UVW > 线织构B19’变体的负面内热膨胀抵消,从而导致整体呈现出极低的平面热膨胀系数。这种的补偿机制同样可以用于在其他形状记忆合金中实现面内低热膨胀。

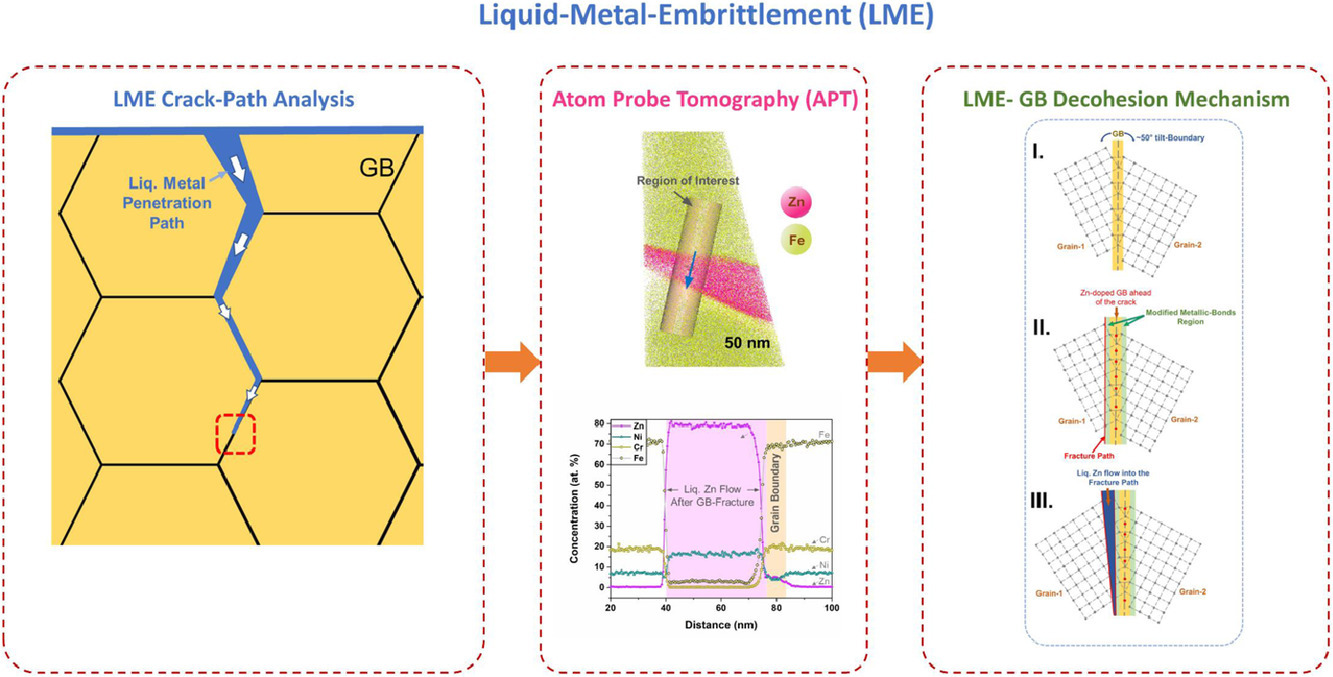

ACTA

Vol. 204, 1 Fed. 2021, 116519

10. Atomic-scale Investigation of Liquid-Metal-Embrittlement Crack-path: Revealing Mechanism and Role of Grain Boundary Chemistry

晶界化学成分对液态金属脆化机制影响的原子尺度研究

M.H. Razmpoosh✉, B. Langelier, E. Marzbanrad, H.S. Zurob, N. Zhou, E. Biro

M.H. Razmpoosh:mhrazmpoosh@uwaterloo.ca

https://doi.org/10.1016/j.actamat.2020.116519

摘要

虽然多晶材料中的大量晶界能够有提高材料强度,但同时也增加在晶界处发生材料劣化的风险,其中就包括液态金属脆化(LME)。在这一过程中,具有侵略性的液态金属劣化固态金属的晶界网络,引起材料断裂。迄今为止,液态金属脆化的研究仅限于微观和介观尺度。然而要充分理解液态金属脆化,还需要对裂纹路径进行原子尺度的研究。本工作中的原子尺度研究首次为最近提出的假设,即电荷密度改变是一种可行的液态金属脆化机制,提供了实验支持。我们成功地对裂纹扩展前沿的晶界脱粘进行了描述。原子探针(APT)表征和分子动力学(MD)模拟较好地解释了为什么高取向差随机晶界比特殊(有序)晶界对液态金属脆化更加敏感。

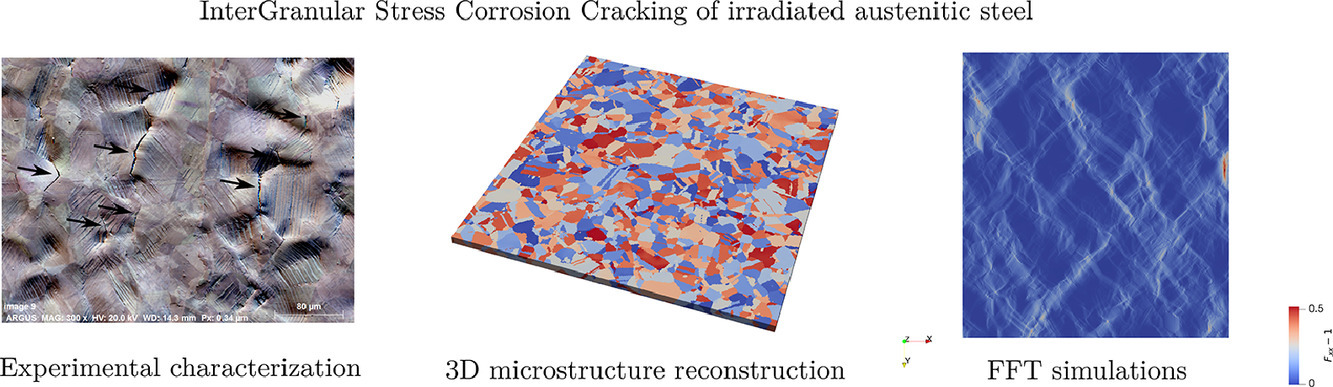

ACTA

Vol. 204, 1 Fed. 2021, 116482

11. A micromechanical analysis of intergranular stress corrosion cracking of an irradiated austenitic stainless steel

辐照诱导奥氏体不锈钢晶间应力腐蚀开裂的微观力学分析研究

D. Liang, J. Hure✉, A. Courcelle, S. El Shawish, B. Tanguy

J. Hure:jeremy.hure@cea.fr

https://doi.org/10.1016/j.actamat.2020.116482

摘要

辐照诱导应力腐蚀(IASCC)是一种核压水堆用奥氏体不锈钢中的材料劣化现象,会导致沿晶裂纹的萌生和扩展。这种现象属于更宽泛的晶间应力腐蚀(IGSCC)的一种。本文对辐照后奥氏体不锈钢的IGSCC进行了微观力学分析,以评估局部开裂条件。我们以压水堆环境中,经质子辐照后产生晶间裂纹的304L不锈钢为研究对象。通过连续切片、背散电子射衍射(EBSD)和两步错位程序重构了样品的三维组织结构,在统计学上对样品的开裂标准进行了评估。此外,我们还提出了一种基于EBSD表征的晶界(GB)法向计算方法。统计分析表明,在与加载方向对齐的晶界法向和Luster-Morris参数较低的方向,裂纹优先萌生。最后,我们基于三维重构组织、傅里叶算法求解和考虑晶界滑移修正的晶体塑性本构方程对材料进行了微观力学模拟。我们通过模拟将实验结果简化为了基于应力的单一判据,并对这种方法的优缺点进行了讨论。

ACTA

Vol. 204, 1 Fed. 2021, 116524

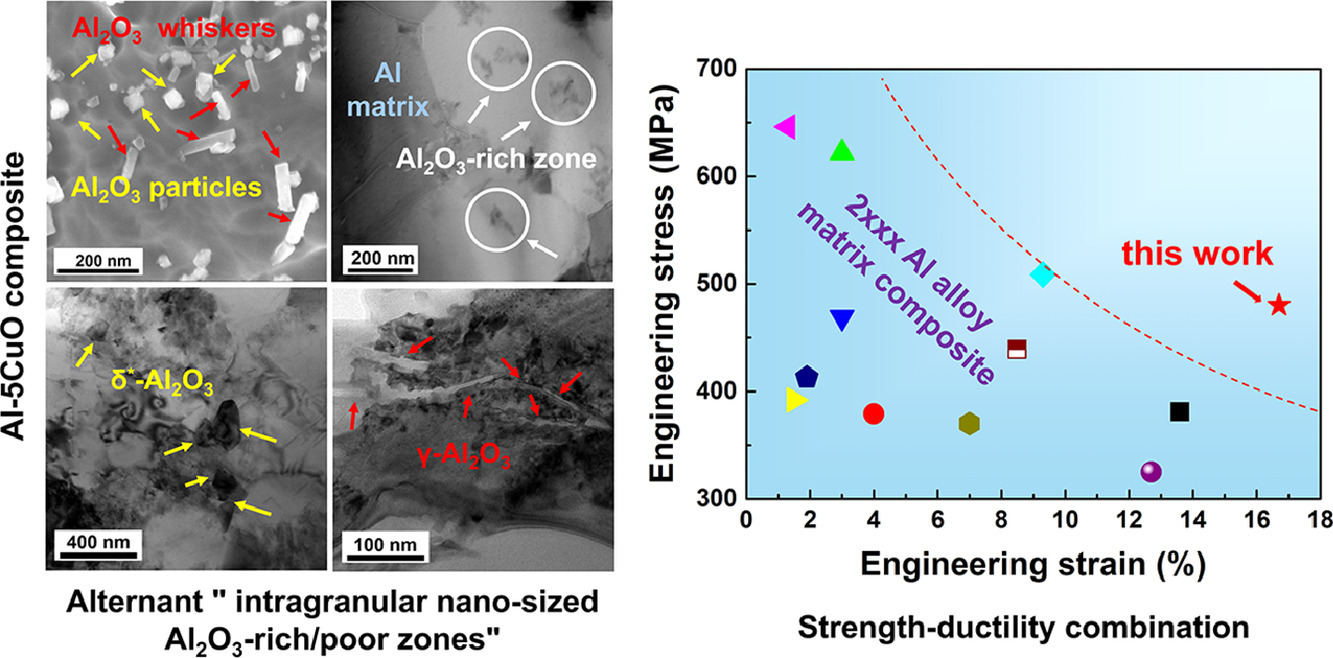

12. Revealing the strengthening and toughening mechanisms of Al-CuO composite fabricated via in-situ solid-state reaction

原位固相反应制备Al-CuO复合材料的强化增韧机理研究

Xudong Rong, Dongdong Zhao✉, Chunnian He, Chunsheng Shi, Enzuo Liu, Naiqin Zhao✉

D. Zhao:ddzhao@tju.edu.cn(天津大学)

N. Zhao:nqzhao@tju.edu.cn(天津大学)

https://doi.org/10.1016/j.actamat.2020.116524

摘要

Al2O3与Al熔体间的界面错配以及晶界处的微米级Al2O3偏析(GBs)等缺陷,是阻碍传统铸造方法制备具有高强度和断裂韧性的Al-CuO复合材料的主要难点。在本工作中,我们通过变速球磨Al-5wt.% CuO粉末,随后进行热压和热处理的方式成功制备了一种新型Al-CuO复合材料。实验表征表明,原位生成的两种类型氧化铝的晶内分布,包括δ*-Al2O3粒子(~ 200 nm)和γ-Al2O3晶须(长度~150nm,厚度~20 nm),主要受由Al-CuO 强烈反应的热效应引起的扩散形核机制控制。制备得到的复合材料的抗拉强度~481 MPa,断裂伸长率~ 16.8%。我们研究了Al2O3的尺寸和空间分布对复合材料力学性能的贡献,并根据Al2O3对Al-CuO复合材料“位错冲击带”和“塑性区”的影响,对其增韧机理进行了讨论。理论分析和断口形貌表明,基体界面得到了强化,同时不均匀分布的Al2O3构成了交替“贫富区”,这些特征有助于提高材料韧性。以上研究结果为提高金属基复合材料的强度和延展性提供了一种新方法。

ACTA

Vol. 204, 1 Fed. 2021, 116522

13. Resolving the porosity-unmelted inclusion dilemma during in-situ alloying of Ti34Nb via laser powder bed fusion

Ti34Nb合金原位激光粉末熔炼过程中气孔-夹杂问题的解决方案

Sheng Huang, R. Lakshmi Narayan✉, Joel Heang Kuan Tan, Swee Leong Sing, Wai Yee Yeong✉

R.L. Narayan:rlnarayan@iitd.ac.in

W.Y. Yeong:wyyeong@ntu.edu.sg

https://doi.org/10.1016/j.actamat.2020.116522

摘要

我们采用系统的参数化实验研究了激光功率(P)、激光速度(VL)和激光形状对原位激光粉末熔练(LPBF)制备Ti34Nb合金的孔隙率、夹杂物含量和显微组织演变的影响。为此,我们在保持能量密度不变的条件下,使用了三套不同的工艺参数对合金进行了打印,随后对打印的样品进行了详细的组织表征和和拉伸试验。我们通过有限元方法(FEM)对单个熔道熔池的演化过程进行了模拟。结果表明,激光形状为帽形、大激光功率 (> 650 W)、高激光速度 (> 650 mm/s)和小扫描宽度条件下,能够形成移动缓慢、且纵横比小的大熔池。这种熔池能够有效地熔化Nb,并将未熔化比例降至最低,而较小熔池纵横比能够抑制孔隙形成。这些熔池特征同时也有利于形成具有强{100}织构的柱状β-Ti组织,这种组织具有优异的强度和弹性模量组合。为了进一步提高该合金的性能,我们对阐述了组织演变的机制和参数优化的原则进行了讨论。

ACTA

Vol. 204, 1 Fed. 2021, 116514

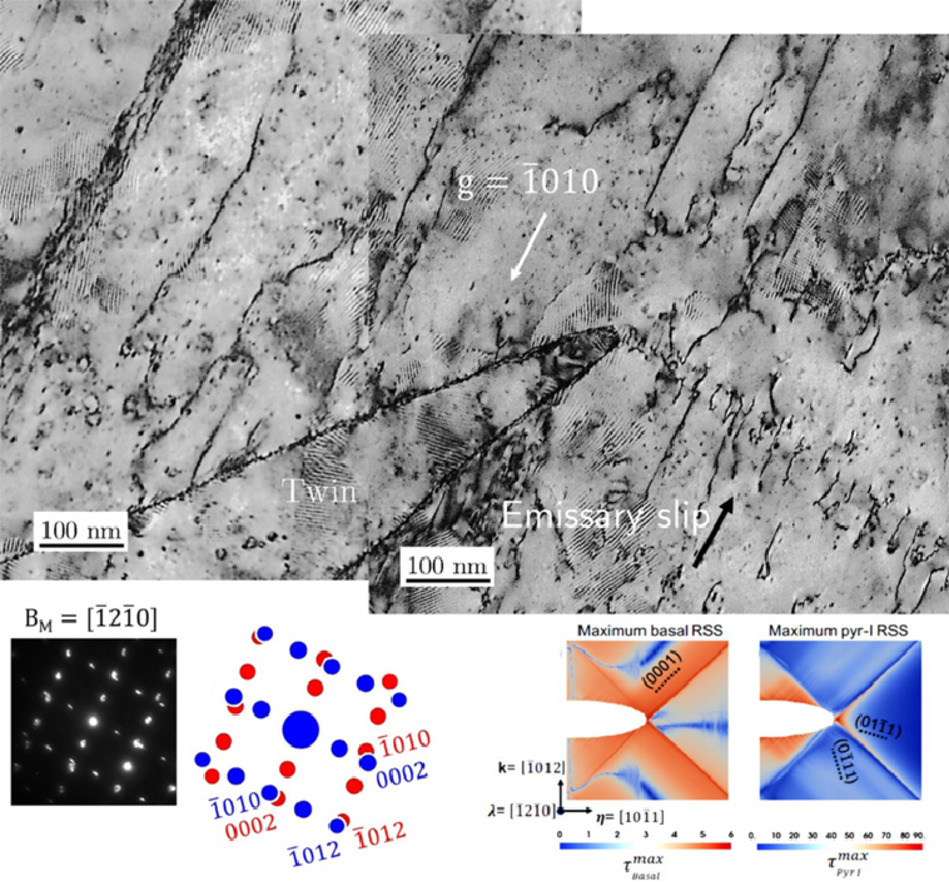

14. Accommodation and formation of {-1012} twins in Mg-Y alloys

Mg-Y合金中{-1012}孪晶的调节与形成

Krishna Yaddanapudi✉, Brandon Leu, M. Arul Kumar, Xin Wang, Julie M. Schoenung, Enrique J. Lavernia, Timothy J. Rupert, Irene J. Beyerlein, Subhash Mahajan

K. Yaddanapudi:grkyaddanapudi@ucdavis.edu

https://doi.org/10.1016/j.actamat.2020.116514

摘要

我们利用透射电子显微镜研究了变形后Mg-Y合金晶粒内部的{-1012}拉伸孪晶。我们终端孪晶和相关滑移结构的晶体学特征进行了量化和分析。为了解释观测到的滑移模式,我们使用了晶体塑性模型模拟计算了终端{-1012}孪晶处的局部应力。结果表明,基底< a >和< c+a >基体滑移均参与调节了孪晶附近产生的塑性应力。我们沿孪晶界观察到了与晶格位错和不完全孪晶相符的缺陷。在此基础之上,我们提出了一种位错反应,成功建立了Mg-Y合金中的基体滑移和{-1012}孪晶之间的相互关系。

ACTA

Vol. 204, 1 Fed. 2021, 116526

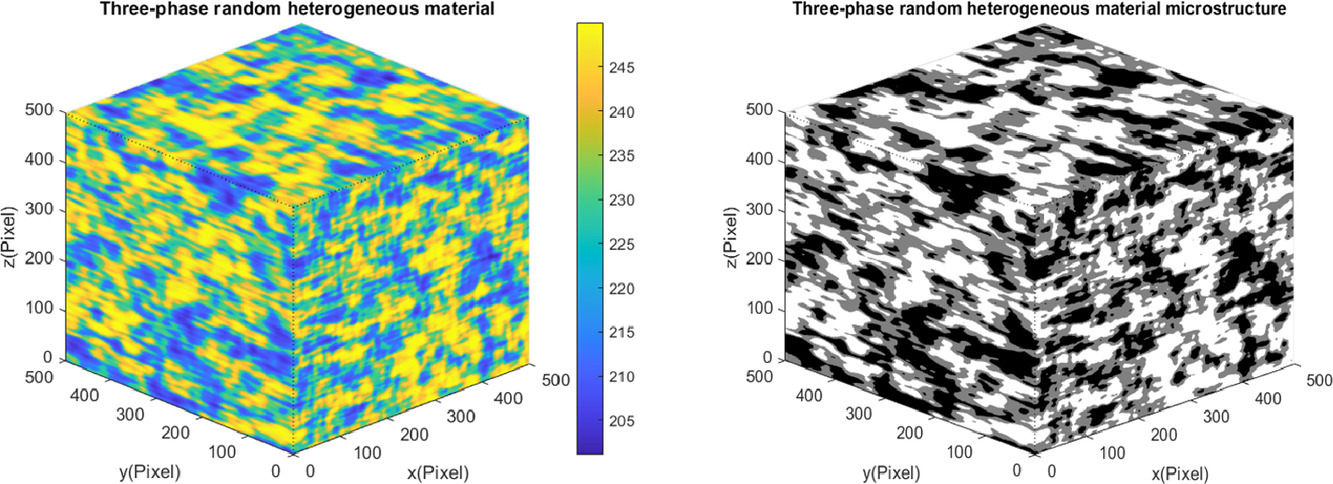

15. Ultra-efficient reconstruction of 3D microstructure and distribution of properties of random heterogeneous materials containing multiple phases

随机非均质多相材料三维组织和性能的超快速重构

Yi Gao, Yang Jiao, Yongming Liu✉

Y. Liu:yongming.liu@asu.edu

https://doi.org/10.1016/j.actamat.2020.116526

摘要

材料的超快速三维组织重够和组织-性能的定量映射是材料集成计算工程(ICME)的重要组成部分。对合金、复合材料、聚合物、多孔介质和颗粒物质等随机非均质材料进行建模尤其具有挑战性,因为这些材料在不同长度尺度下的复杂微观组织具有不确定性,性能也表现出很强的随机性和变化性。在本研究中,我们提出了一种显式混合随机场(MEF)模型来同时表征和重构多相随机材料的性能和微观结构。该方法具有超高的计算效率,且只需要极少的映射和特性输入数据。材料性能场通过由高斯随机场的非线性映射显式产生的非高斯随机场建模。相应的微观组织由基于材料性能场得到的离散相指标来表示。我们通过采用Karhunen-Loève (K-L) 分解展开算法,极大地降低了高维和高分辨率重构的计算成本和内存需求。从二维到三维,从双相到多相,从各向同性到各向异性的材料重构,证明了该方法的可行性和优越性。结果表明,重建500×500×500像素分辨率的三维材料只需约几秒。具有不确定性量化能力的显式组织-性能映射表达式可直接嵌入ICME框架,用于材料设计和优化。

ACTA

Vol. 204, 1 Fed. 2021, 116523

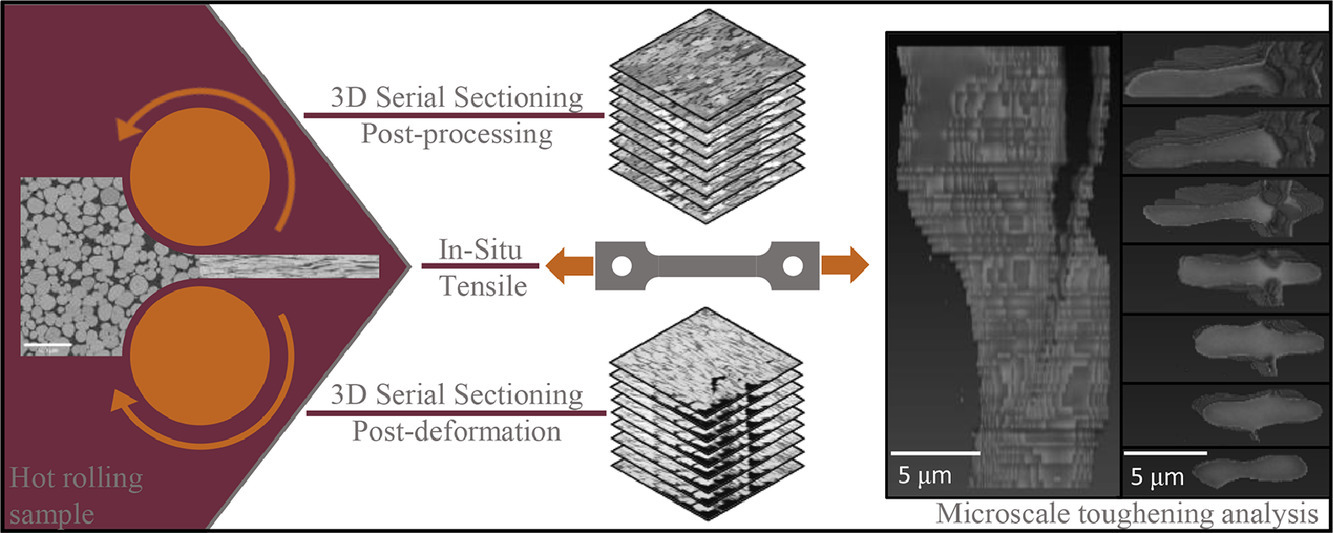

16. Characterization of ductile phase toughening mechanisms in a hot-rolled tungsten heavy alloy

热轧钨重合金韧性相增韧机制的表征研究

James V. Haag IV✉, Danny J. Edwards✉, Charles H. Henager Jr. ✉, Wahyu Setyawan✉, Jing Wang✉, Mitsuhiro Murayama✉

J.V. Haag IV :haagjac@vt.edu

D.J. Edwards :dan.edwards@pnnl.gov

C.H. Henager Jr.:chuck.henager@pnnl.gov

W.Setyawan:wahyu.setyawan@pnnl.gov

J. Wang:jing.wang@pnnl.gov

M. Murayama:murayama@vt.edu

https://doi.org/10.1016/j.actamat.2020.116523

摘要

重钨合金(WHAs)是一种增韧合金。由于其优异的强度和延展性综合力学性能而作为核聚变反应堆等离子体材料组件用多晶钨的备选方案,受到广泛关注。为了验证WHAs在聚变反应堆极端恶劣环境下的可用性,首先需要了解与其组织与性能的关系。在此,我们选择了一种90W-7Ni-3Fe WHA合金,研究了热机械处理和组织调控对这种双相金属材料力学性能的的影响。试样的原位拉伸试验和三维显微结构分析均表明,钨晶界处存在被韧性相钝化和抑制的微裂纹,界面脱粘的情况较少被观察到。对该合金进行热机械处理后,发现球形脆性相畴变为长片状,韧性相的连通性大幅降低,并对材料的性能有显著影响。以上关于材料韧性相增韧机制的表征加深了我们对这类合金性能背后物理机制的理解,并揭示了不同相之间惊人的界面强度。

ACTA

Vol. 204, 1 Fed. 2021, 116494

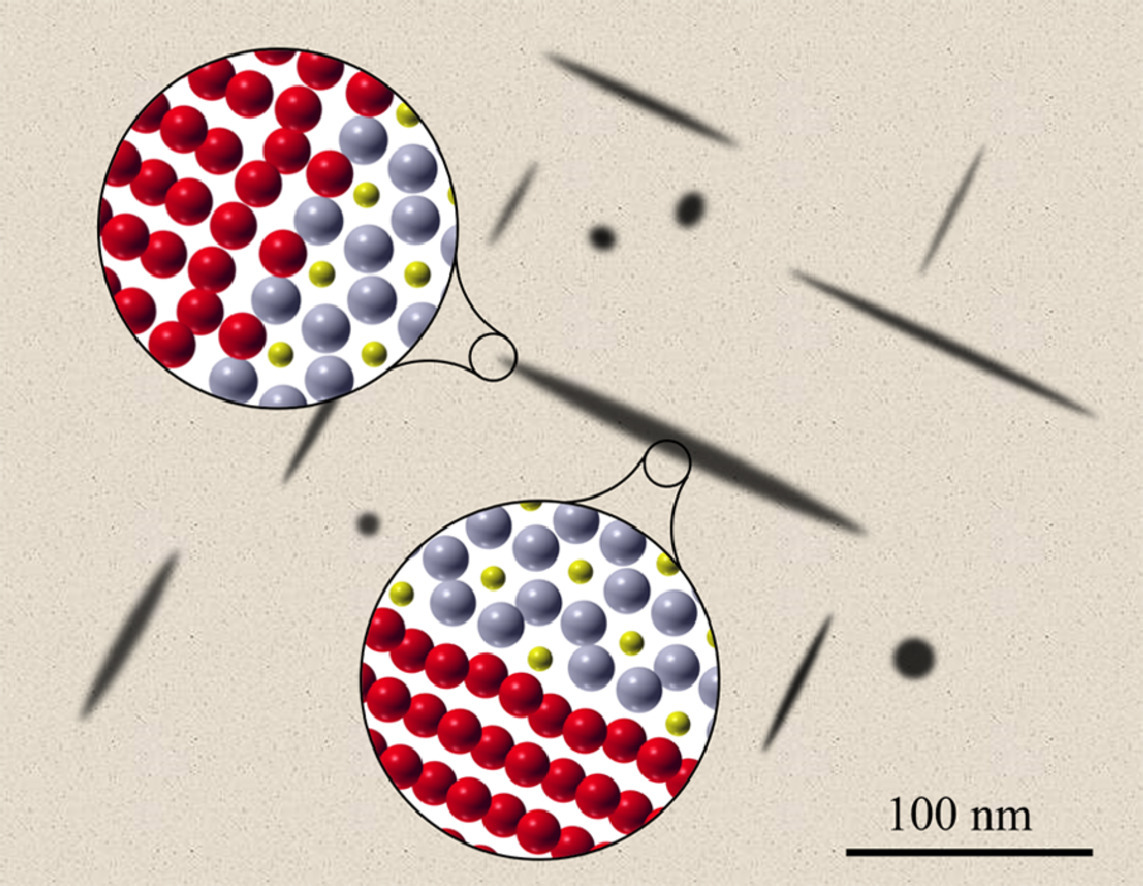

17. Ultra-high strength and plasticity mediated by partial dislocations and defect networks: Part II: Layer thickness effect

分位错和缺陷网络致材料超高强度和塑性中的层厚效应

Ruizhe Su, Dajla Neffati, Qiang Li, Sichuang Xue, Cuncai Fan, Jaehun Cho, Yifan Zhang, Jin Li, Haiyan Wang, Yashashree Kulkarni, Xinghang Zhang✉

X. Zhang:xzhang98@purdue.edu

https://doi.org/10.1016/j.actamat.2020.116494

摘要

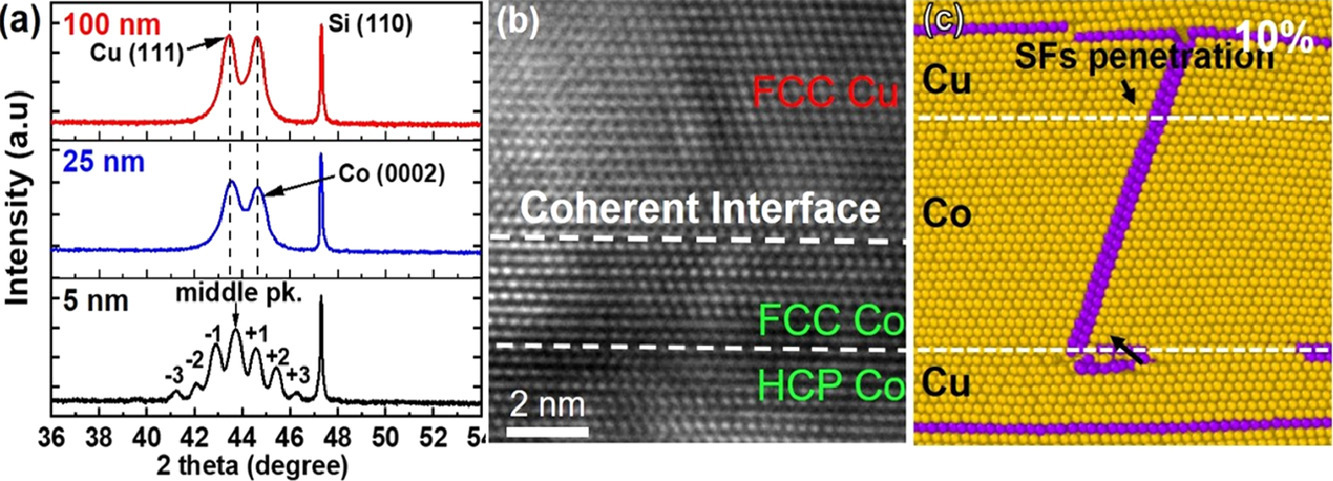

层厚对金属纳米叠层结构力学行为的影响已被广泛研究。在最近的一项研究中,我们发现了一种特殊的缺陷网络,其中包括层界面、层错和孪晶界,对Cu/Co多层结构的强度起到重要贡献。作为以上工作的后续,我们研究了层厚与这种缺陷网络之间的相互影响。我们以单层厚度分别为5、25和100 nm的强织构织构Cu (111)/Co(0002)多层结构为研究对象,通过原位微柱压缩试验,发现25 nm Cu/Co多层结构的强度远高于100 nm和5 nm多层结构。对形变样品的透射电镜分析和分子动力学模拟表明,缺陷密度随层厚的变化对材料强度有显著影响。本研究为高强度、可形变金属材料的缺陷网络优化设计提供了新的视角。