金属顶刊双语导读丨Acta Mater. Vol.213,1 Jul. 2021(上)

2021-08-08 来源:Goal Science

本期包含金属材料领域论文11篇,涵盖了马氏体、不锈钢、中熵合金等,国内科研单位包括北京计算科学研究中心、沈阳金属所、北京航空航天大学、东北大学等(通讯作者单位)。

Vol. 213 目录

1. An in-situ synchrotron diffraction study of stress relaxation in titanium: Effect of temperature and oxygen on cold dwell fatigue

温度和氧含量对钛中应力松弛影响的原位同步衍射研究

2. Atomistic modelling of thermal-cycling rejuvenation in metallic glasses

金属玻璃热循环恢复的原子尺度模型

3. Breakdown of the Hall-Petch relationship in extremely fine nanograined body-centered cubic Mo alloys

纳米晶体心立方Mo合金中Hall-Petch关系的失效原因

4. Coarsening of martensite with multiple generations of twins in laser additively manufactured Ti6Al4V

激光增材制造Ti6Al4V中的孪晶马氏体粗化

5. Dislocation electron tomography: A technique to characterize the dislocation microstructure evolution in zirconium alloys under irradiation

辐照态锆合金中位错微观结构演化的表征

6. Giant heterogeneous magnetostriction induced by charge accumulation-mediated nanoinclusion formation in dual-phase nanostructured systems

双相纳米结构体系中纳米夹杂引起的显著非均匀磁致伸缩效应

7. Influence of internal hydrogen content on the evolved microstructure beneath fatigue striations in 316L austenitic stainless steel

氢含量对316L奥氏体不锈钢疲劳组织演化的影响

8. In situ studies of liquid-liquid phase separation, solidification sequence and dendrite growth kinetics in electrostatically levitated Ti–Y alloys

静电悬浮Ti-Y合金中液相分离、凝固顺序和枝晶生长的动力学原位研究

9. Interaction between nucleant particles and a solid-liquid interface in Al-4.5Cu alloy

Al-4.5Cu合金中形核粒子与固液界面的相互作用研究

10. Mechanical properties and deformation mechanisms of a Ni2Co1Fe1V0.5Mo0.2 medium-entropy alloy at elevated temperatures

Ni2Co1Fe1V0.5Mo0.2中熵合金的高温力学性能及变形机制研究

11. Mesoscale hetero-deformation induced (HDI) stress in FeAl-based metallic-intermetallic laminate (MIL) composites

FeAl基金属间化合物层状复合材料的介观尺度不均匀变形诱导应力研究

ACTA

Vol. 213,1 Jul. 2021, 116937

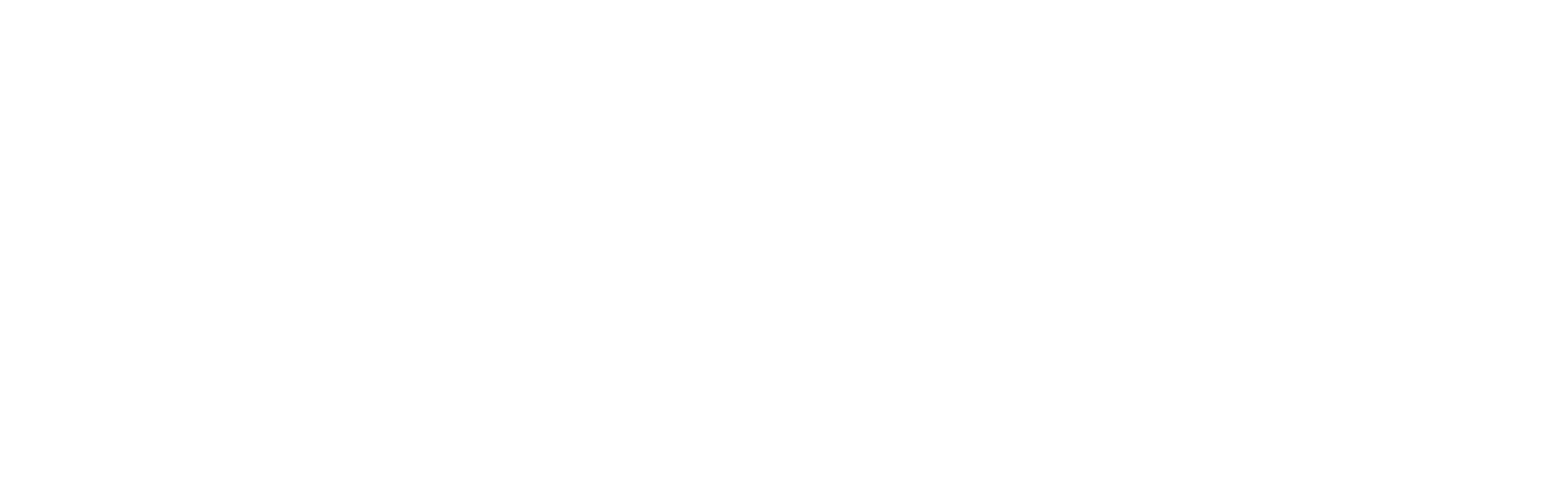

1. An in-situ synchrotron diffraction study of stress relaxation in titanium: Effect of temperature and oxygen on cold dwell fatigue

温度和氧含量对钛中应力松弛影响的原位同步衍射研究

Yi Xiong✉, Phani S. Karamched, Chi-Toan Nguyen, David M. Collins, Nicolò Grilli, Christopher M. Magazzeni, Edmund Tarletond, Angus J. Wilkinson

Y. Xiong:yi.xiong@materials.ox.ac.uk

https://doi.org/10.1016/j.actamat.2021.116937

摘要

Ti合金在室温循环加载过程中的应力残余会导致疲劳寿命的急剧下降。为了更好地理解这一现象,需要对合金中主要滑移系随时间的变化进行分析,尤其是阐明温度和合金元素的影响。本研究中,我们在4个温度条件下(室温,75°C, 145°C和250°C),使用同步X射线衍射对两种不同氧含量的商业纯钛样品(1级和4级)在应力松弛过程塑性随时间的变化进行了表征。我们通过测量晶格应变松弛响应,对晶体塑性有限元模型进行了修正,从而确定了主棱柱滑移和基底滑移系统中位错运动的关键参数随时间和氧含量的变化。研究表明,75℃时材料的劣化最为严重,由于棱柱和基底滑移系统活跃,导致松弛周期中宏观塑性应变积累明显。随着温度的升高,热对位错滑移的影响逐渐超过机械能。我们发现氧能够改变滑移系统的临界分切应力,且氧对棱柱滑移的强化作用大于基底滑移用。这种效应在高氧含量的商业纯钛中十分显著。

ACTA

Vol. 213,1 Jul. 2021, 116952

2. Atomistic modelling of thermal-cycling rejuvenation in metallic glasses

金属玻璃热循环恢复的原子尺度模型

Baoshuang Shang, Weihua Wang, Alan Lindsay Greer, Pengfei Guan✉

P. Guan:pguan@csrc.ac.cn(北京计算科学研究中心)

https://doi.org/10.1016/j.actamat.2021.116952

摘要

金属玻璃经室温和低温之间反复循环可导致材料在快速冷却过程中形成高能态。这种现象是十分出人意料的,因为它是在很小的宏观应变和远低于热激活结构变化温度条件下发生的,这对于材料的塑性具有重要意义。我们通过分子动力学模拟,阐明了热循环诱导弛豫和回复的机制。数十次的热循环可以驱使原子发生局部重排,从而逐渐消除最初的玻璃结构。这一过程与每个热循环加热阶段金属玻璃固有的结构不均一性有关。虽然分子动力学模拟的时间较短,但模拟能够很好地复现实验观测到的物理现象。以上研究对于通过热循环调控金属玻璃性能具有指导意义。

ACTA

Vol. 213,1 Jul. 2021, 116950

3. Breakdown of the Hall-Petch relationship in extremely fine nanograined body-centered cubic Mo alloys

纳米晶体心立方Mo合金中Hall-Petch关系的失效原因

F.H. Duan, Y. Naunheim, C.A. Schuh✉, Y. Li✉

C.A. Schuh:schuh@mit.edu

Y. Li:liyi@imr.ac.cn (沈阳金属研)

https://doi.org/10.1016/j.actamat.2021.116950

摘要

人们对FCC金属纳米晶的力学性能和变形行为进行了大量研究,而对bcc金属相关研究则却较少。我们对晶粒尺寸120 ~ 4nm的BCC Mo(O)的硬度和变形行为进行了研究,其中既包括Hall-Petch公式适用的范围,也包括不适用的范围(11 ~ 4nm)。当材料晶粒尺寸为11nm时,材料的硬度最高,达17.3GPa。材料在晶粒尺寸极小时的失效可能与激活体积、应力集中等有关。而较大晶粒尺寸下的失效则与晶界剪切、晶间变形等有关。超细晶中引起应力集中的剪切带尺寸远大于晶粒尺寸的大剪切带的形成有关。因此超细晶中的变形行为可能更加类似于玻璃的变形,这与材料中无序结构所占比例增加自洽。

ACTA

Vol. 213,1 Jul. 2021, 116954

4. Coarsening of martensite with multiple generations of twins in laser additively manufactured Ti6Al4V

激光增材制造Ti6Al4V中的孪晶马氏体粗化

Mangesh V. Pantawane, Shashank Sharma, Abhishek Sharma, Sriswaroop Dasari, Srikumar Banerjee, Rajarshi Banerjee, Narendra B. Dahotre✉

N.B. Dahotre:narendra.dahotre@unt.edu

https://doi.org/10.1016/j.actamat.2021.116954

摘要

激光粉末熔炼过程中复杂的热动力学条件大大提高了我们理解增材制造Ti6Al4V内部孪晶马氏体结构演化的难度。我们通过基于有限元方法的热、动力学模型,结合扫描电镜和透射电镜实验,对此进行了研究。为了解增材制造过程中激光热处理对马氏体和孪晶形貌演化的影响,我们分别进行了单道次、双道次、三道次激光和传统锻造态材料热处理(1323K固溶后水淬至室温)对比实验。研究表明,与增材制造的Ti6Al4V相比,水淬Ti6Al4V样品中的马氏体板条更细。随着激光道次增加,马氏体板条逐渐粗化并发生变形。此外,在增材制造Ti6Al4V中还观测到了孪晶的多次生成,而在固溶水淬的Ti6Al4V则很少发现。多代孪晶也是单一激光轨迹处理的变形Ti6Al4V的显著特征。这些具有独特形态和晶体学特征的马氏体演化过程与模拟预测的激光粉末熔炼增材制造过程中的热、动力学条件密切相关。

ACTA

Vol. 213,1 Jul. 2021, 116964

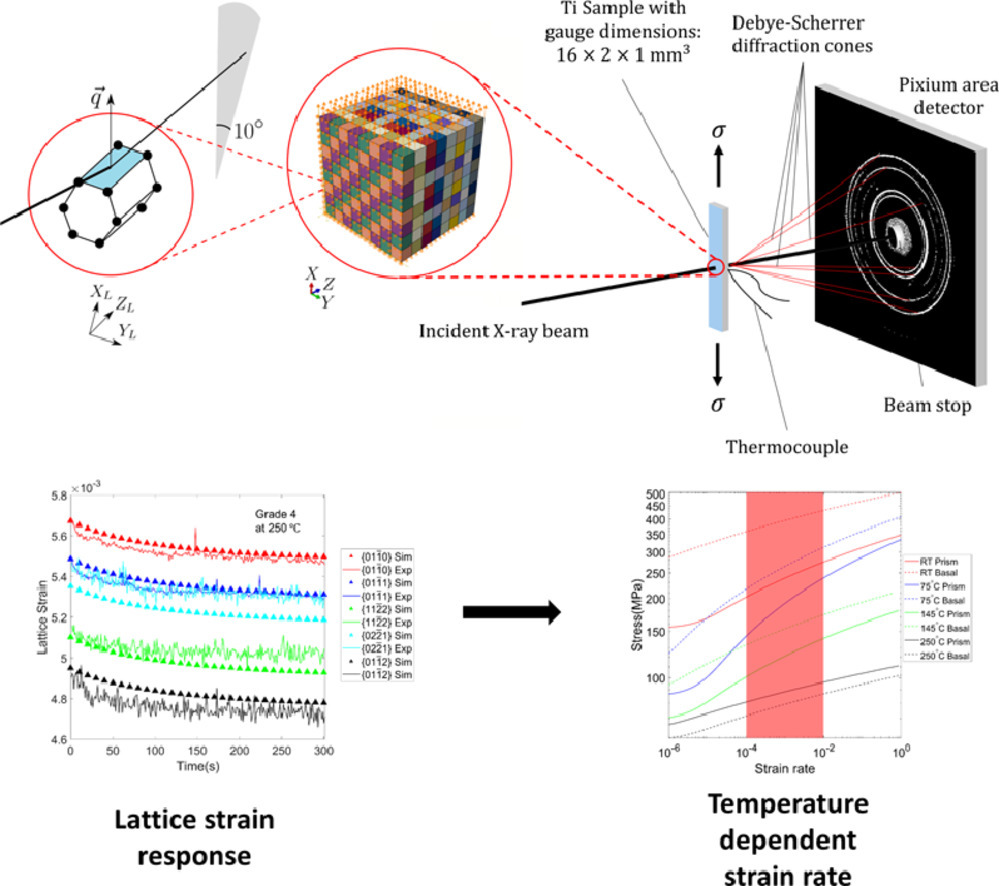

5. Dislocation electron tomography: A technique to characterize the dislocation microstructure evolution in zirconium alloys under irradiation

辐照态锆合金中位错微观结构演化的表征

Alexandre Mussi✉, Ahmed Addad, Fabien Onimus

A. Mussi:alexandre.mussi@univ-lille.fr

https://doi.org/10.1016/j.actamat.2021.116964

摘要

我们利用衍射-对比电子扫描技术对锆合金辐照前后的位错三维微观结构进行了研究。辐照前,我们对材料在室温下进行了拉伸。材料应变后出现大量具有<a>伯氏矢量的螺位错。通过对含有非螺位错段的惯析面进行分析,我们发现这类位错主要在棱柱面内滑移,而较少在一阶锥面内滑移。辐照后,我们在材料中观测到了具有<a>伯氏矢量的位错环。结果表明,位错环的惯析面位于{10-10}面周围,最多可向(0001)和{11-20}面倾斜20°。此外,我们证实了螺位错在辐照下发生了攀移。攀移过程中位错间发生相互作用。辐照下位错攀移是锆合金在机械载荷和辐照共同作用下在反应堆内变形的重要机制。该过程中位错与位错环间的相互作用对变形也有重要影响。

ACTA

Vol. 213,1 Jul. 2021, 116975

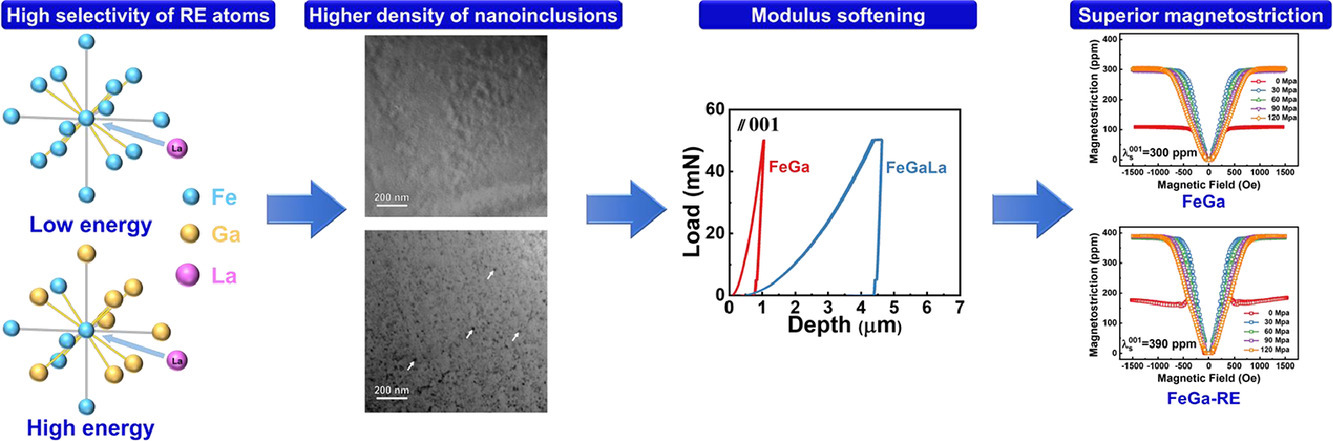

6. Giant heterogeneous magnetostriction induced by charge accumulation-mediated nanoinclusion formation in dual-phase nanostructured systems

双相纳米结构体系中纳米夹杂引起的显著非均匀磁致伸缩效应

Yijun Chen, Zhongheng Fu, Yuye Wu✉, Yichen Xu, Yu Xiao, Jingmin Wang, Ruifeng Zhang, Chengbao Jiang✉

Y. Wu:wuyuye@buaa.edu.cn(北京航空航天大学)

C. Jiang:jiangcb@buaa.edu.cn(北京航空航天大学)

https://doi.org/10.1016/j.actamat.2021.116975

摘要

目前关于双相纳米结构超磁致伸缩效应的形成原因仍存在争议。已有研究表明,形成四方纳米夹杂会导致局部各向异性增大,从而增大磁致伸缩。纳米夹杂对晶格弹性常数的影响是另一个关键因素,但相关研究尚不深入。我们基于稀土掺杂FeGa单晶中的理论计算和实验结果提出了一种机制。由于稀土原子与Fe原子的键合作用强于Ga原子,因此掺杂有效增加了A2基体中纳米夹杂的密度。结果表明,随着纳米夹杂物密度的增加,弹性常数c12相比c11显著增加。由于磁致伸缩(λ001)与c11−c12存在直接关联,因此磁致伸缩显著增强。同时由于夹杂引起的晶格软化,稀土掺杂后单晶样品的磁致伸缩可达390ppm。以上研究揭示了稀土原子对FeGa单晶磁致伸缩的贡献,为双相磁致伸缩材料的设计提供了指导。

ACTA

Vol. 213,1 Jul. 2021, 116957

7. Influence of internal hydrogen content on the evolved microstructure beneath fatigue striations in 316L austenitic stainless steel

氢含量对316L奥氏体不锈钢疲劳组织演化的影响

K.E. Nygren, A. Nagao, S. Wang, P. Sofronis, I.M. Robertson✉

I.M. Robertson:irobertson@wisc.edu, ian.robertson@wisc.edu

https://doi.org/10.1016/j.actamat.2021.116957

摘要

我们研究了SUS316L奥氏体不锈钢中氢(最高达到104.2 mass ppm)对拉伸和疲劳性能的影响。研究表明,氢对拉伸性能的影响极小,但会降低材料的疲劳寿命,且这种影响不是单调变化的。疲劳断口下的组织形貌在裂纹长度和氢含量等方面各有异同。氢的存在使得材料中形成了具有更厚胞壁的小位错胞,并改变了变形孪晶的分布。随着氢浓度的增加,疲劳响应非线性变化,这是由于材料在高浓度氢状态下的宏观性能发生了转变。鉴于我们的研究重点是将氢引起的组织变化与材料力学性能的变化建立联系,因此我们主要从氢对局部塑性的增强作用出发,对实验结果进行了讨论。

ACTA

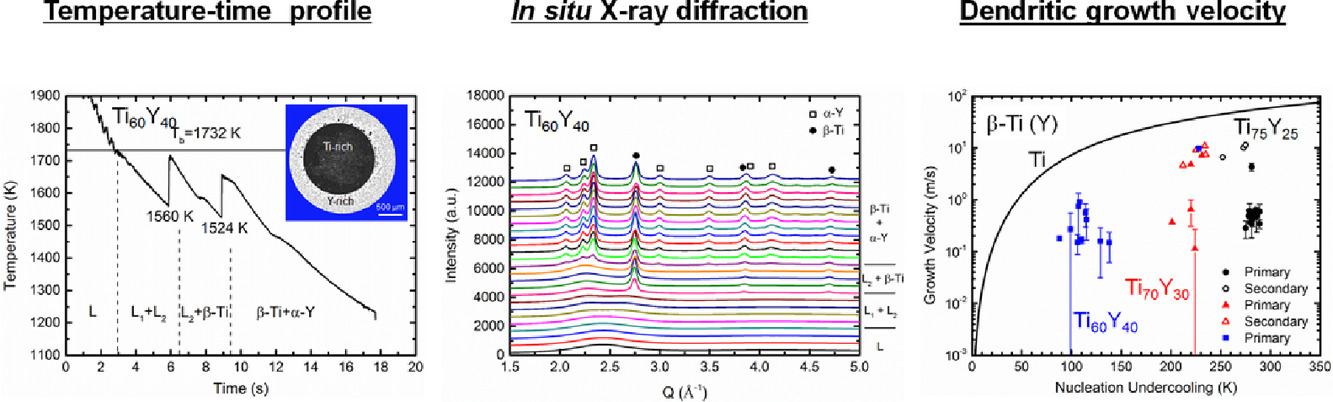

Vol. 213,1 Jul. 2021, 116962

8. In situ studies of liquid-liquid phase separation, solidification sequence and dendrite growth kinetics in electrostatically levitated Ti–Y alloys

静电悬浮Ti-Y合金中液相分离、凝固顺序和枝晶生长的动力学原位研究

Dandan Zhao, Fan Yang Dirk Holland-Moritz, Matthias Kolbe, Thomas Buslaps, Jianrong Gao✉

J. Gao:jgao@mail.neu.edu.cn(东北大学)

https://doi.org/10.1016/j.actamat.2021.116962

摘要

我们采用了静电悬浮方法对亚偏晶Ti75Y25、近偏晶Ti70Y30和过偏晶Ti60Y40熔体进行了过冷凝固。通过高能X射线衍射(HEXRD)和光学成像技术对过冷熔体中的液相分离、凝固顺序和枝晶生长速度进行了原位研究。研究表明,三种Ti−Y成分的过冷熔体在凝固前分离成富Ti熔液和富Y熔液。熔液的凝固顺序取决于富Y液体中HCP α-Y的形核和富Ti液中BCC β-Ti的形核。α-Y和β-Ti的枝晶生长速度只与时间有关,而不随形核过冷度的增加而增加。这一独特的长大动力学特征可能是由于生长的枝晶和熔液之间的动态相互作用导致的。扫描电镜表征表明,相分离样品凝固后形成核壳结构或岛状结构。对凝固过程中液相分离和液相-枝晶相互作用的深入研究能够更好地帮助我们理解这一形貌产生的原因。

ACTA

Vol. 213,1 Jul. 2021, 116956

9. Interaction between nucleant particles and a solid-liquid interface in Al-4.5Cu alloy

Al-4.5Cu合金中形核粒子与固液界面的相互作用研究

Y. Liu, Q. Han✉

Q. Han:hanq@purdue.edu

https://doi.org/10.1016/j.actamat.2021.116956

摘要

我们通过添加卤化物,在Al-4.5 wt % Cu合金中原位制备了Al3Ti和TiB2粒子。熔融卤盐能够使氧化物溶解在熔融金属中,从而确保新形成的Al3Ti和TiB2粒子与熔融金属有密切的界面。在熔体中加入过量的钛,可以保证颗粒与熔融合金之间的浸润角较小,使得粒子显著减小铝合金的晶粒尺寸。当粒子被前进的固-液界面吞噬到固体中时,这种粒子/基体系统的总界面能减小,从而使得这一过程可以不断发生。实验结果表明,无论枝晶生长速度如何,这些粒子实际上总是被生长的枝晶推入枝晶间区域。在本研究的实验条件下,基于界面能相互作用的粒子推动机制似乎不适用于这一体系。分析表明,这些粒子在固液界面紧密接触,范德华力能够发挥显著作用之前,就不断被长大的枝晶推动。糊状区液体的收缩流动对粒子的运动起到重要作用。

ACTA

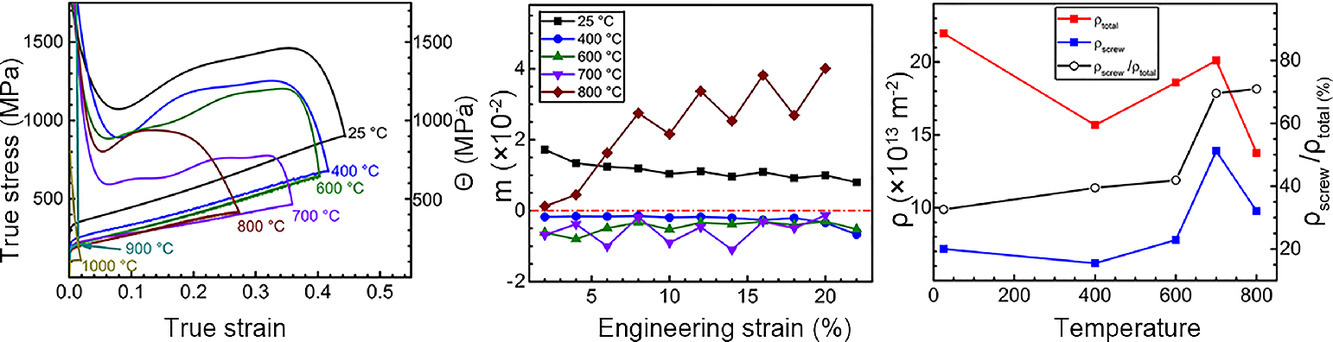

Vol. 213,1 Jul. 2021, 116982

10. Mechanical properties and deformation mechanisms of a Ni2Co1Fe1V0.5Mo0.2 medium-entropy alloy at elevated temperatures

Ni2Co1Fe1V0.5Mo0.2中熵合金的高温力学性能及变形机制研究

Wei Jiang, Shengyun Yuan, Yang Cao✉, Yong Zhang✉, Yonghao Zhao✉

Y. Cao:y.cao@njust.edu.cn, cao_yang_leo@hotmail.com(南京理工大学)

Y. Zhang:yong@njust.edu.cn(南京理工大学)

Y. Zhao:yhzhao@njust.edu.cn(南京理工大学)

https://doi.org/10.1016/j.actamat.2021.116982

摘要

我们铸造了一种单相面心立方结构的Ni2Co1Fe1V0.5Mo0.2中熵合金(MEA)。这种铸态中熵合金具有优异的加工硬化能力、屈服强度、抗拉强度和均匀延伸率。在25 ~ 800℃的拉伸变形过程中,中熵合金在弹塑性转变后的应变硬化率呈上升趋势。大量溶质原子和高密度位错提供了充足的背应力强化,使得应变硬化率上升。研究表明,温度对中熵合金力学性能的影响与位错结构、位错密度和动态应变时效密切相关。随着变形温度的升高,位错密度发生波动,螺位错比例不断增加。溶质钉扎和位错森林强化是引起400℃-700℃范围内应变硬化率变化的原因。而在800℃时,随着应变的增加,主要变形机制由位错森林切割机制转变为位错交叉滑移,导致材料的应变硬化速率急剧上升。另一方面,动态应变时效造成塑性失稳,不利中熵合金的应变硬化。以上研究对中熵、高熵合金在高温下的力学性能调控具有指导意义。

ACTA

Vol. 213,1 Jul. 2021, 116949

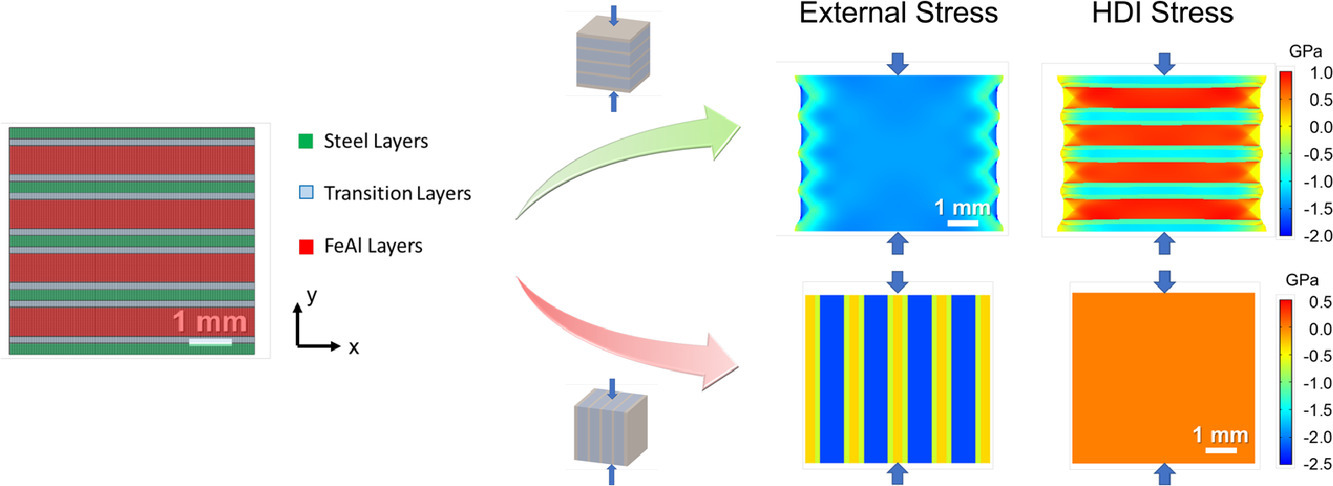

11. Mesoscale hetero-deformation induced (HDI) stress in FeAl-based metallic-intermetallic laminate (MIL) composites

FeAl基金属间化合物层状复合材料的介观尺度不均匀变形诱导应力研究

Haoren Wang, Rui Kou, Haozhe Yi, Samuel Figueroa, Kenneth S. Vecchio✉

K.S. Vecchio:kvecchio@ucsd.edu

https://doi.org/10.1016/j.actamat.2021.116949

摘要

我们采用层箔法合成了单相FeAl层状材料,并对FeAl基金属间化合物层状(MIL)复合材料的断裂机理进行了研究。我们通过压缩实验研究了单相FeAl的力学性能和裂纹演化规律。显微组织和成分表征表明,单相FeAl和FeAl基复合材料具有相似的层状组织。当受压方向垂直于叠层方向时,两种材料均由于FeAl相沿加载方向开裂最终导致失效。MIL复合材料中的FeAl层由于介观不均匀变形引起的应力(HDI)而受到拉伸作用,这加速了裂纹的形核和扩展,并导致材料发生破坏。430SS-FeAl和304SS-FeAl MIL复合材料具有相似的组织和成分,但强度差异很大,我们通过有限元模拟对此进行了解释。当受压方向平行于叠层方向时,介观HDI效应可以忽略,几何必要位错的堆积可以提高复合材料的性能。我们通过四点弯试验对FeAl基MIL复合材料的断裂韧性进行了表征,结果表明,FeAl基MIL复合材料比单相FeAl具有更高的断裂韧性。