金属顶刊双语导读丨Acta Mater. Vol.213,1 Jul. 2021(下)

2021-08-29 来源:Goal Science

本期包含金属材料领域论文11篇,涵盖了金属玻璃、增材制造、高熵合金等,国内科研单位包括北京科技大学等(通讯作者单位)。

Vol. 213 目录

1. Microstructural and compositional design principles for Mo-V-Nb-Ti-Zr multi-principal element alloys: a high-throughput first-principles study

Mo-V-Nb-Ti-Zr多主元合金组织和成分设计的高通量第一性原理研究

2. Microstructure and properties of NbVZr refractory complex concentrated alloys

NbVZr合金的组织与性能研究

3. Nanoporosity evolution during dealloying: Interplay between chemical dissolution, material defects, coarsening and local structural rearrangements over long timescales

脱合金化过程中化学溶解、材料缺陷、粗化和局部结构重排在长时间尺度上的相互作用研究

4. Noble gas bubbles in bcc metals: Ab initio-based theory and kinetic Monte Carlo modeling

BCC金属中惰性气泡的第一性原理计算和动力学蒙特卡罗模拟

5. Novel class of nanostructured metallic glass films with superior and tunable mechanical properties

具有优越和可调力学性能的新型纳米结构金属玻璃薄膜

6. Optimizing the cellular automata finite element model for additive manufacturing to simulate large microstructures

增材制造大面积组织的元胞自动机有限元模型优化

7. Shear fracture in bulk metallic glass composites

块体金属玻璃复合材料的剪切断裂机理研究

8. Simulations of primary damage in a High Entropy Alloy: Probing enhanced radiation resistance

基于对初级损伤的模拟探究高熵合金的抗辐照机理

9. Strain hardening mediated by coherent nanoprecipitates in ultrahigh-strength steels

共格纳米析出对超高强度钢应变硬化的影响

10. Tool-workpiece stick-slip conditions and their effects on torque and heat generation rate in the friction stir welding

搅拌摩擦焊接过程中的工具-工件粘滑状态及其对扭矩和产热率的影响

11. Twin-boundary assisted crack tip plasticity and toughening in lamellar γ-TiAl

孪晶界对层状γ-TiAl裂纹尖端塑性的影响及其增韧作用研究

ACTA

Vol. 213,1 Jul. 2021, 116958

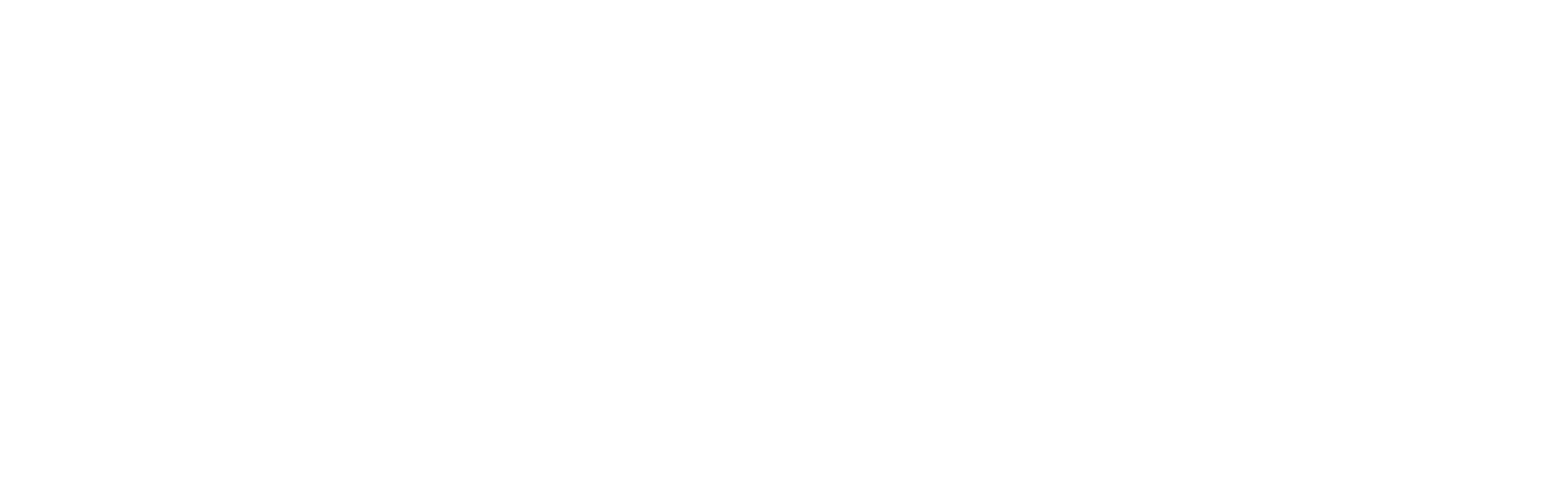

1. Microstructural and compositional design principles for Mo-V-Nb-Ti-Zr multi-principal element alloys: a high-throughput first-principles study

Mo-V-Nb-Ti-Zr多主元合金组织和成分设计的高通量第一性原理研究

Zhidong Leong✉, Upadrasta Ramamurty✉, Teck Leong Tan✉

Z. Leong:leong_zhidong@ihpc.a-star.edu.sg

U. Ramamurty:uram@ntu.edu.sg

T.L. Tan:tantl@ihpc.a-star.edu.sg

https://doi.org/10.1016/j.actamat.2021.116958

摘要

由于多主元合金具有广阔的成分空间,因此对其进行组织设计和优化十分困难。我们对Mo-V-Nb-Ti-Zr多主元合金进行了高通量第一性原理研究,以深入了解这一体系原子尺度的微观结构。借助蒙特卡罗模拟,我们揭示了多主元合金在广阔组成空间中微观结构的控制原理,包括非等原子比的二元、三元和四元合金。基于完全固溶体的Hume-Rothery规则,我们提出了一个定量表达式来从组成预测固溶的形成。我们的模型结果与大量实验观测一致,并对成分空间中未探索的区域提供了预测。该工作从元素的偏聚和团簇倾向的角度阐明了多主元合金的微观结构,为具有优异性能多主元合金的设计提供了指导。

ACTA

Vol. 213,1 Jul. 2021, 116919

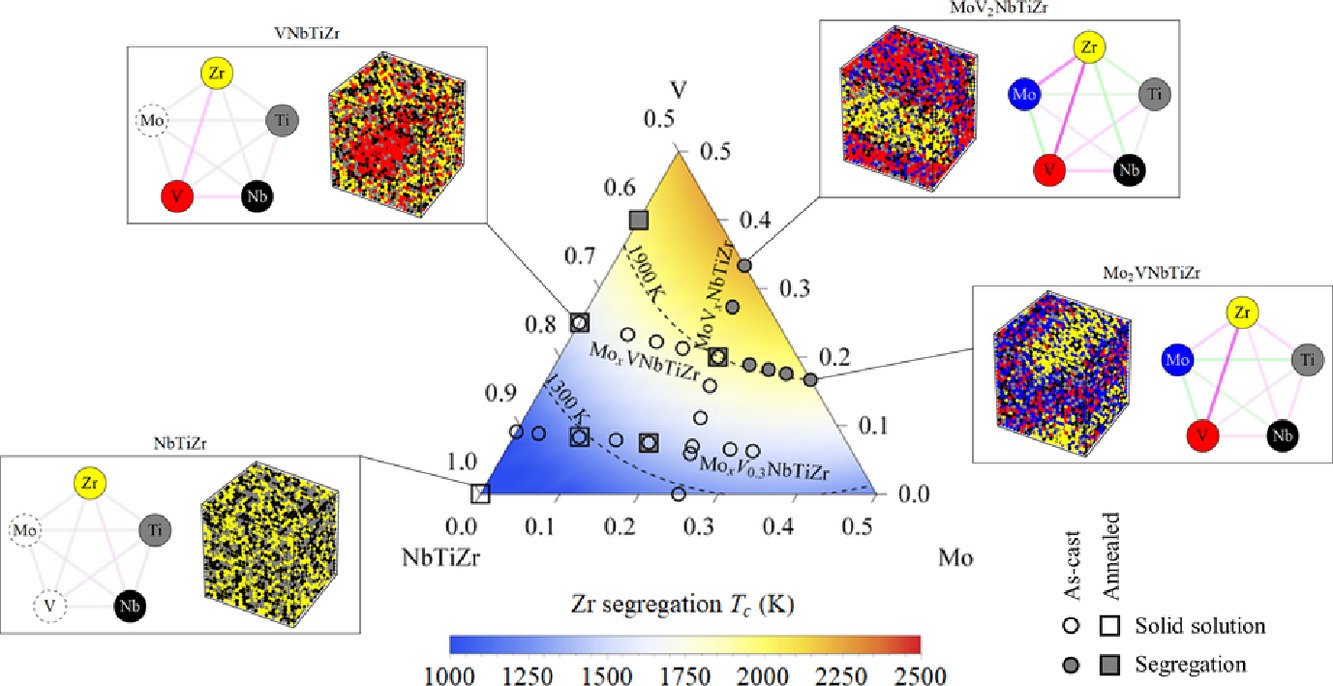

2. Microstructure and properties of NbVZr refractory complex concentrated alloys

NbVZr合金的组织与性能研究

Mu Li, Zhaohan Zhang, Arashdeep S. Thind, Guodong Ren, Rohan Mishra, Katharine M Flores

https://doi.org/10.1016/j.actamat.2021.116919

摘要

我们对等原子比NbVZr合金的组织和力学性能进行了研究。铸态和激光处理样品均表现为BCC枝晶固溶体,枝晶间存在六方C14和立方C15 Laves相。我们基于第一性原理计算,对Laves相的稳定性进行了讨论,发现Nb能够提高C14和C15相的稳定性。通过纳米压痕和对变形样品的TEM表征,我们发现Laves相能够阻碍位错运动,提高材料强度。我们在Laves相区域发现了大量的层错,这与第一性原理预测的低层错能吻合,并能够提高材料塑性。本研究为基于高通量方法系统研究难熔复杂合金中金属间化合物的稳定性提供了范例。这些金属间化合物对合金的综合力学性能具有重要作用。

ACTA

Vol. 213,1 Jul. 2021, 116974

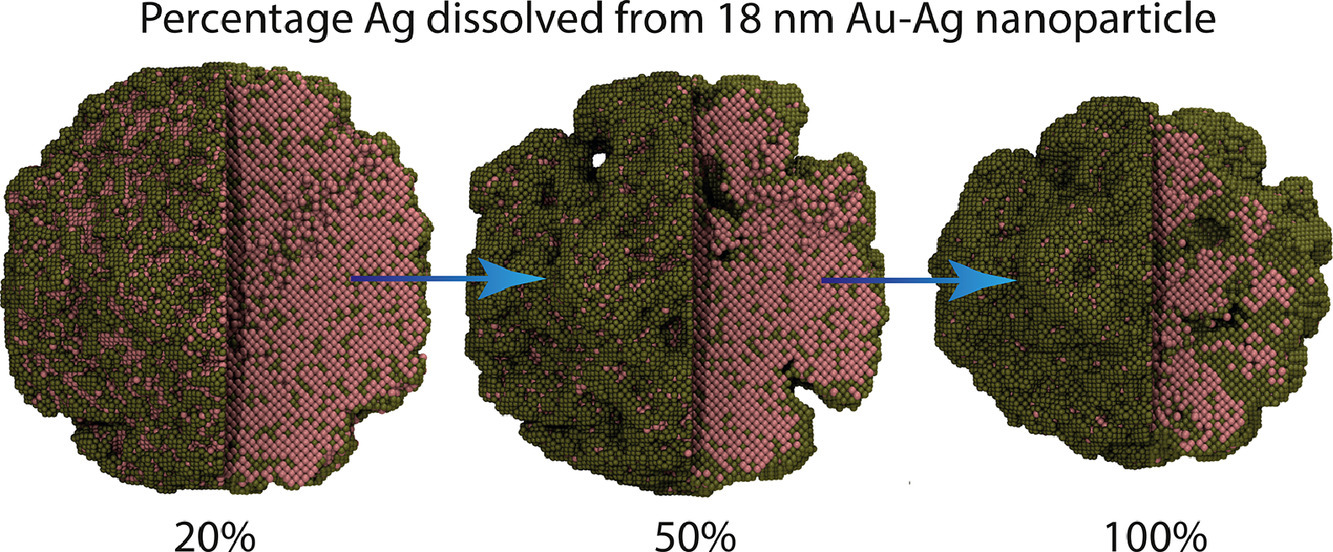

3. Nanoporosity evolution during dealloying: Interplay between chemical dissolution, material defects, coarsening and local structural rearrangements over long timescales

脱合金化过程中化学溶解、材料缺陷、粗化和局部结构重排在长时间尺度上的相互作用研究

Aditya Shankar Sandupatla, Abhijit Chatterjee

A. Chatterjee:abhijit@che.iitb.ac.in

https://doi.org/10.1016/j.actamat.2021.116974

摘要

合金的选择性溶解/脱合金化是合成纳米多孔结构的常用方法。在几分钟的脱合金化过程中,材料的组织结构演化涉及化学溶解、纽带形成、纽带粗化、局部塌陷和缺陷形成的复杂相互作用。纽带松弛的时间尺度在皮秒-纳秒量级,而溶解的时间尺度在秒量级。本研究中,我们建立了一种新的多尺度框架,将晶格动力学蒙特卡罗方法(KMC)和分子动力学(MD)进行了结合。我们的算法对时间尺度进行了分割,发现了以下关键特征:(1)在溶解过程中不发生纽带断裂 (2) 模型可以获得比KMC模型直径粗10倍的纽带 (3) 溶解50-60%时表面积最大 (4) 纽带断裂导致了粒子收缩 (5) 溶解50%以上,孔隙率基本保持恒定 (6)位错密度随着电活性原子溶解的增多而增加。此外,我们也研究了粒子尺寸、温度、合金成分和电位的影响。以上研究表明,在模拟合金选择性溶解过程时,考虑纽带的持续松弛是十分必要的。

ACTA

Vol. 213,1 Jul. 2021, 116961

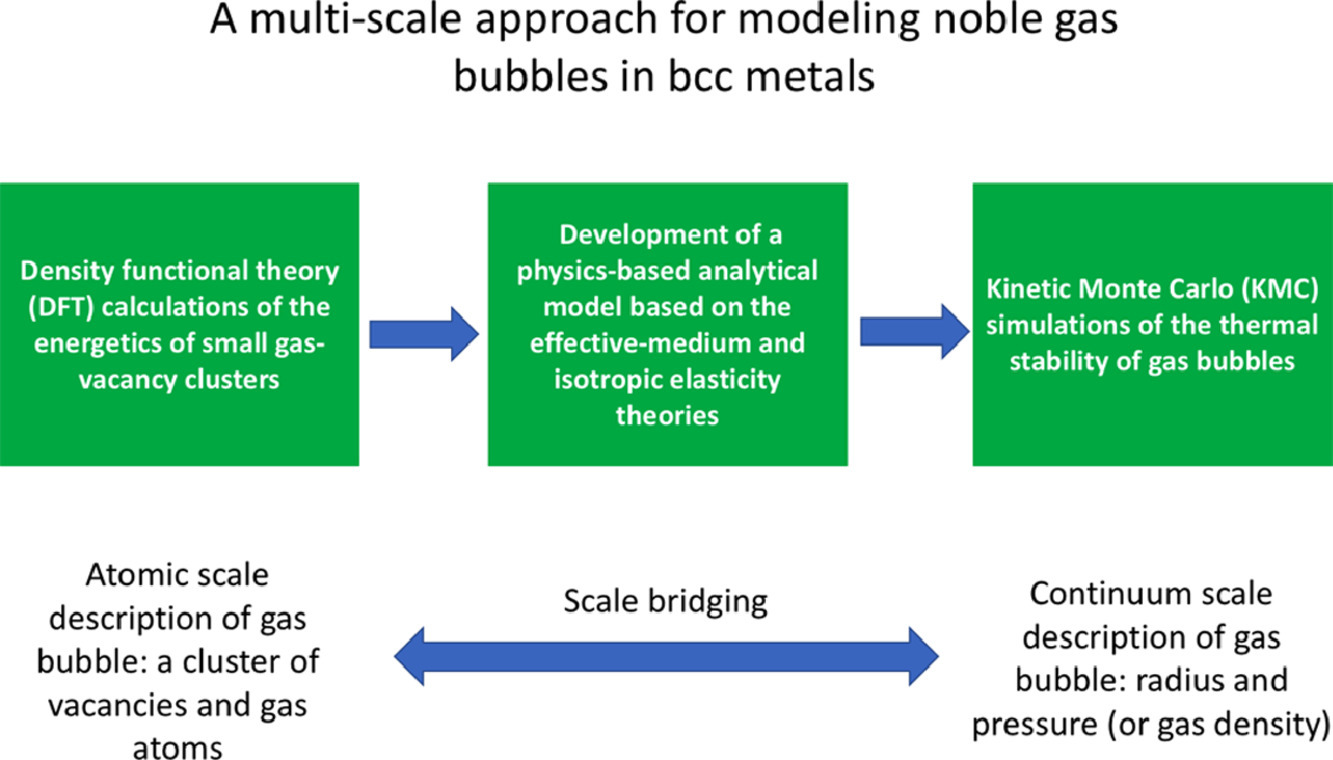

4. Noble gas bubbles in bcc metals: Ab initio-based theory and kinetic Monte Carlo modeling

BCC金属中惰性气泡的第一性原理计算和动力学蒙特卡罗模拟

Chao Jiang✉, Yongfeng Zhang, Larry K. Aagesen, Andrea M. Jokisaari, Cheng Sun, Jian Gan

C. Jiang:chao.jiang@inl.gov

https://doi.org/10.1016/j.actamat.2021.116961

摘要

了解稀有气体与金属的相互作用对核反应堆的抗辐照结构材料设计具有重要意义。我们提出了一个普适的理论,用于描述He、Ne、Ar、Kr等惰性气泡在5B (V, Nb, Ta), 6B (Cr, Mo, W)和8B (Fe)族bcc金属中的能量状态。模型基于有效介质和各向同性弹性理论,并通过密度泛函理论(DFT)对气体-空位团簇的计算对模型参数进行了量化。通过将我们的模型与蒙特卡罗模拟结合,我们预测了惰性气泡的寿命和Ostwald熟化。研究发现,bcc金属中的Ne、Ar、Kr泡的热稳定性比He泡高得多,能够较好地抑制Ostwald熟化。我们进一步阐明了大原子序数惰性气泡稳定的原因。我们的理论发现与退火条件下He泡超晶格(GBS)粗化的实验观察一致,并为bcc U-Mo合金中裂变GBS在高温下的异常稳定提供了新的见解。研究的计算结果与文献中已有的热氦脱附光谱实验结果比较吻合。

ACTA

Vol. 213,1 Jul. 2021, 116955

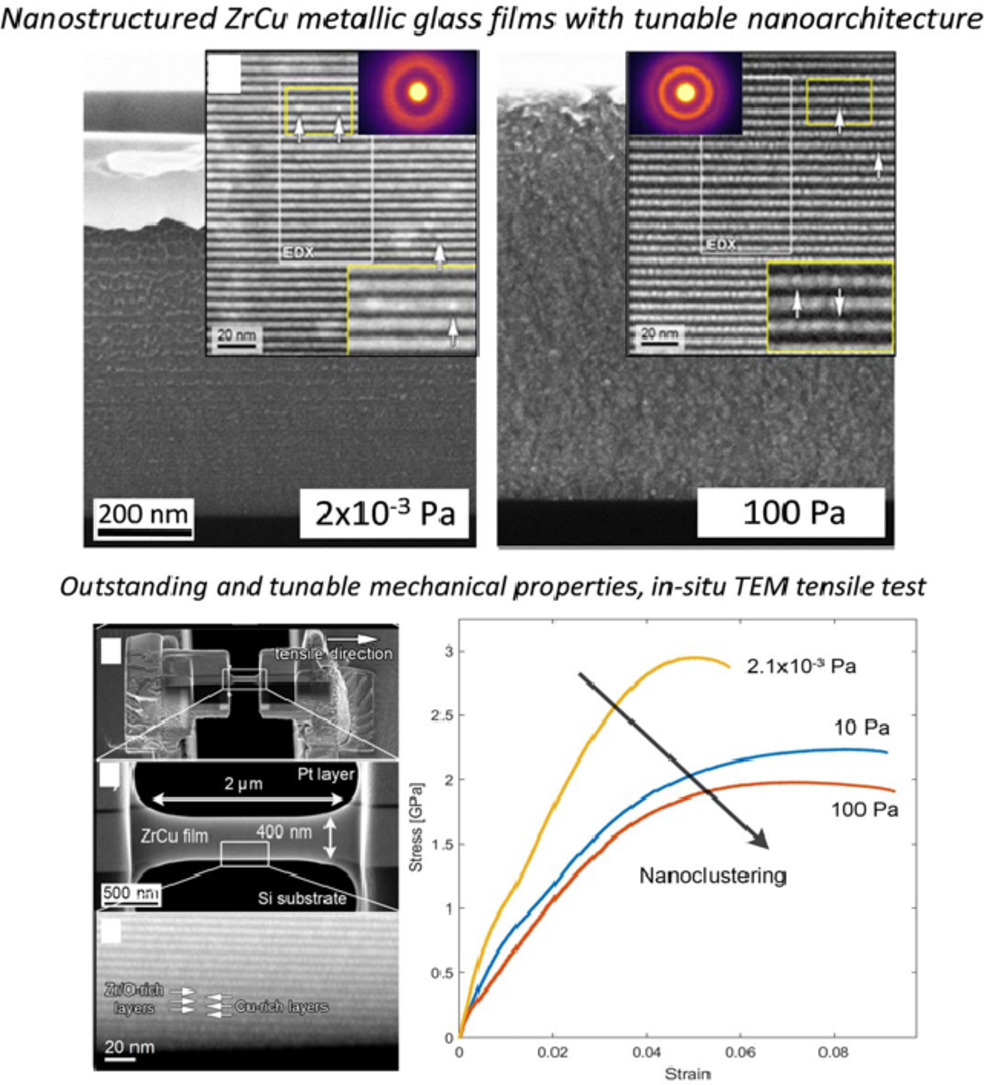

5. Novel class of nanostructured metallic glass films with superior and tunable mechanical properties

具有优越和可调力学性能的新型纳米结构金属玻璃薄膜

M. Ghidelli✉, A. Orekhov, A. Li Bassi, G. Terraneo, P. Djemia, G. Abadias, M. Nordd, A. Béché, N. Gauquelin, J. Verbeeck, J.-P. Raskin, D. Schryvers, T. Pardoen, H. Idrissi✉

M. Ghidelli:matteo.ghidelli@lspm.cnrs.fr

H. Idrissi:hosni.idrissi@uclouvain.be

https://doi.org/10.1016/j.actamat.2021.116955

摘要

我们利用脉冲激光沉积方法制备得到了一种新型的具有优良力学性能的纳米结构Zr50Cu50 (at.%)金属玻璃薄膜。通过对工艺进行调控,可以合成多种薄膜结构,包括致密非晶、嵌有纳米晶的非晶和非晶纳米颗粒等。我们发现了一种独特的致密自组装纳米层状原子排列结构,即交替的富Cu和富Zn/O纳米层组成的非晶态或晶态-非晶态复合结构。这种纳米结构具有优越的力学性能,硬度达10GPa,弹性模量达140 GPa,总断裂伸长率>9%。并且这种优异的强度/延性平衡还可以通过薄膜结构实现进一步调控。以上结果对高性能纳米金属玻璃薄膜合成具有重要意义,这一材料在微电子和涂装领域可能具有良好的应用潜力。

ACTA

Vol. 213,1 Jul. 2021, 116930

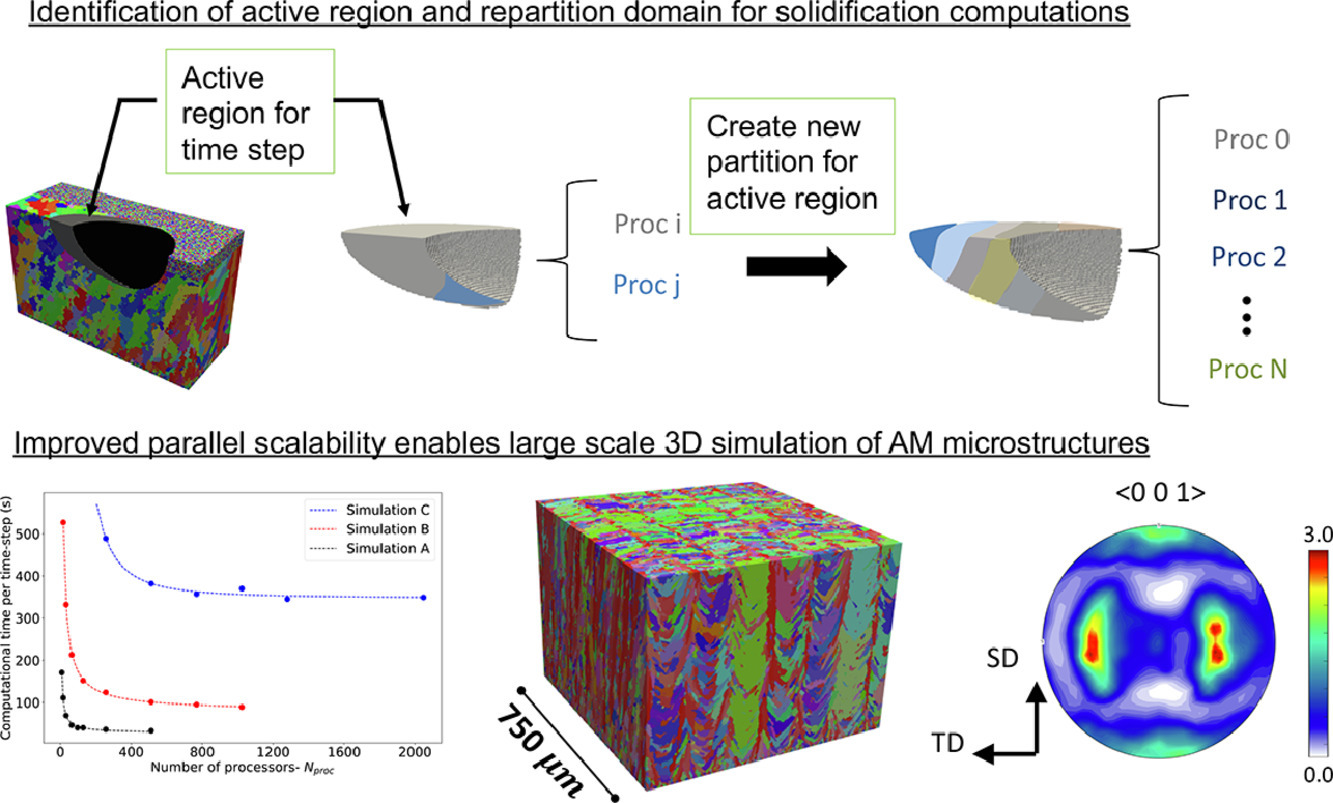

6. Optimizing the cellular automata finite element model for additive manufacturing to simulate large microstructures

增材制造大面积组织的元胞自动机有限元模型优化

Kirubel Teferr✉, David J. Rowenhorst

K. Teferra:kirubel.teferra@nrl.navy.mil

https://doi.org/10.1016/j.actamat.2021.116930

摘要

我们提出了一种元胞自动机有限元(CAFE)模型,用于模拟增材制造中的材料凝固过程。在任何时间,熔池都是一个高度局域的高能区域。温度场随时间演化的尺度远大于晶粒凝固的时间尺度。我们提出了一种将时间尺度离散化的方法,从而在激光扫描的每个时间步长独立对凝固进行分析。在每个时间步长中,材料只有一小部分过冷但尚未凝固的区域。我们找到这一区域,并建立分区,使得凝固计算的算力分配达到平衡。研究表明,这一方法通过并行运算极大地提高了计算效率。这种改进对三维多晶组织的形貌和织构模拟具有重要意义。我们用模型对316L不锈钢的激光粉末熔炼过程进行了验证,模拟得到的多晶组织形貌和织构与实验数据吻合较好。我们对不同的激光扫描模式进行了模拟,以阐明其对材料组织特征的影响。

ACTA

Vol. 213,1 Jul. 2021, 116963

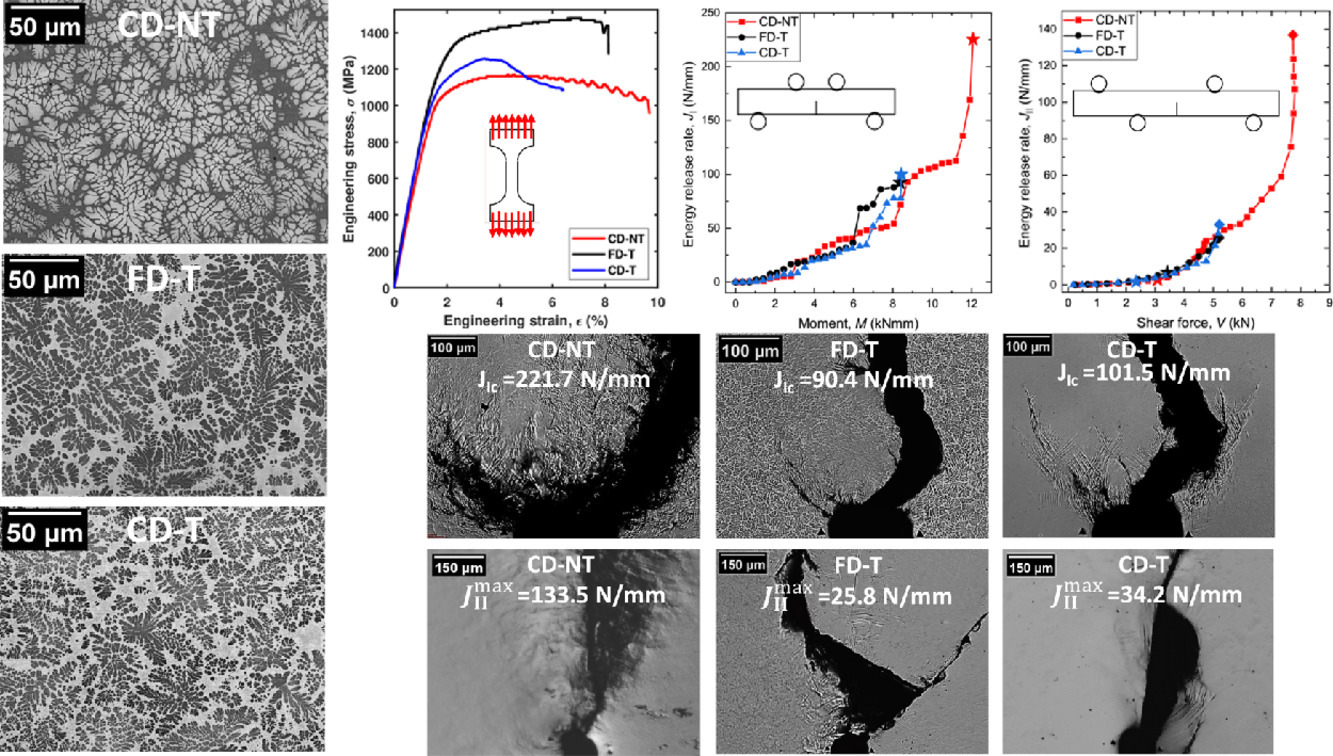

7. Shear fracture in bulk metallic glass composites

块体金属玻璃复合材料的剪切断裂机理研究

Devashish Rajpoot, R. Lakshmi Narayan✉, Long Zhang✉, Punit Kumar, Haifeng Zhang, Parag Tandaiya✉, Upadrasta Ramamurty

R.L. Narayan:rlnarayan@mse.iitd.ac.in

L. Zhang:zhanglong@imr.ac.cn(沈阳金属所)

P. Tandaiya:parag.ut@iitb.ac.in

https://doi.org/10.1016/j.actamat.2021.116963

摘要

我们对含有相变或非相变β-Ti枝晶的块体金属玻璃基复合材料(BMGCs) 在剪切和张开模式下的断裂行为进行了研究。实验结果表明,材料在II型断裂模式下的韧性显著低于I型断裂模式,这主要是由于前者处于剪切应力状态下,容易产生剪切带。I型模式下的裂纹扩展不明显,而II型模式下裂纹发生了一定扩展。尽管相变β-Ti具有较强的应变硬化能力,能够提高材料延性,但在两种断裂模式下,含有非相变粗枝晶的BMGCs均表现出了更高的韧性。I型和II型试样的断口表面特征和尖端剪切带形貌表明,尽管枝晶和剪切带间存在相互作用,但金属玻璃基复合材料的断裂准则和断裂机制与金属玻璃相同。我们基于非晶基体的弛豫焓、枝晶尺寸和枝晶的相变趋势对剪切带向裂纹转变的影响,对BMGCs的断裂行为进行了解释。以上研究对提高含相变枝晶BMGCs的断裂韧性具有指导作用。

ACTA

Vol. 213,1 Jul. 2021, 116951

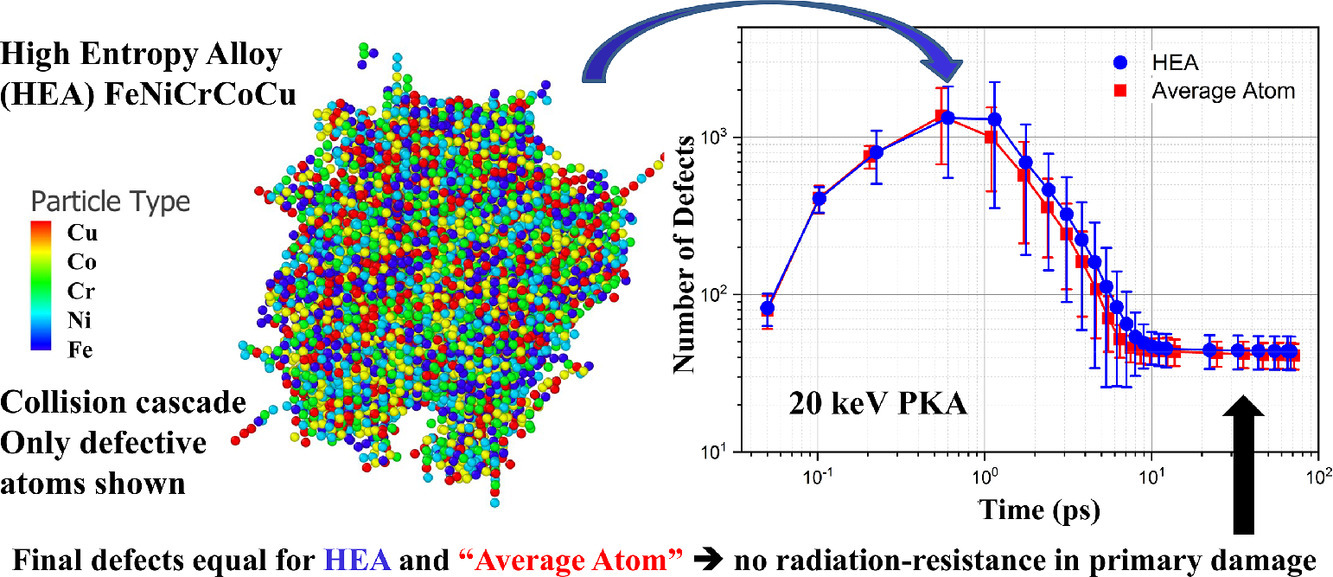

8. Simulations of primary damage in a High Entropy Alloy: Probing enhanced radiation resistance

基于对初级损伤的模拟探究高熵合金的抗辐照机理

O.R. Deluigi, R.C. Pasianot, F.J. Valencia, A. Caro, D. Farkas, E.M. Bringa✉

E.M. Bringa:ebringa@yahoo.com

https://doi.org/10.1016/j.actamat.2021.116951

摘要

高熵合金(High Entropy Alloys, HEA)作为一种可能的抗辐照材料而受到广发关注。高熵合金具有一些独特的特征,比如由于原子无序排列导致热导率低,以及化学成分复杂引起某些特殊缺陷等。本研究中,我们采用分子动力学模拟了FCC 等原子比FeNiCrCoCu高熵合金和纯镍中的级联损伤,以研究材料在辐照早期(0.1ns)的损伤行为。模拟条件为室温,撞击粒子能量为10、20、40eV。我们通过修正精确描述了级联过程中原子的短程相互作用。结果表明,在所有模拟条件下,高熵合金中的平均缺陷数都少于纯Ni。然而,两种材料中的Frenkel对、缺陷团簇尺寸分布等均可在误差范围内认为基本没有差别。纯Ni材料中的缺陷产生模型可以较好地预测合金中的剩余Frenkel对数量。这表明,实验中观察到的高熵合金的抗辐照能力可能并非是由于化学成分复杂导致初级损伤减少,而是由长时间缺陷演化引起。

ACTA

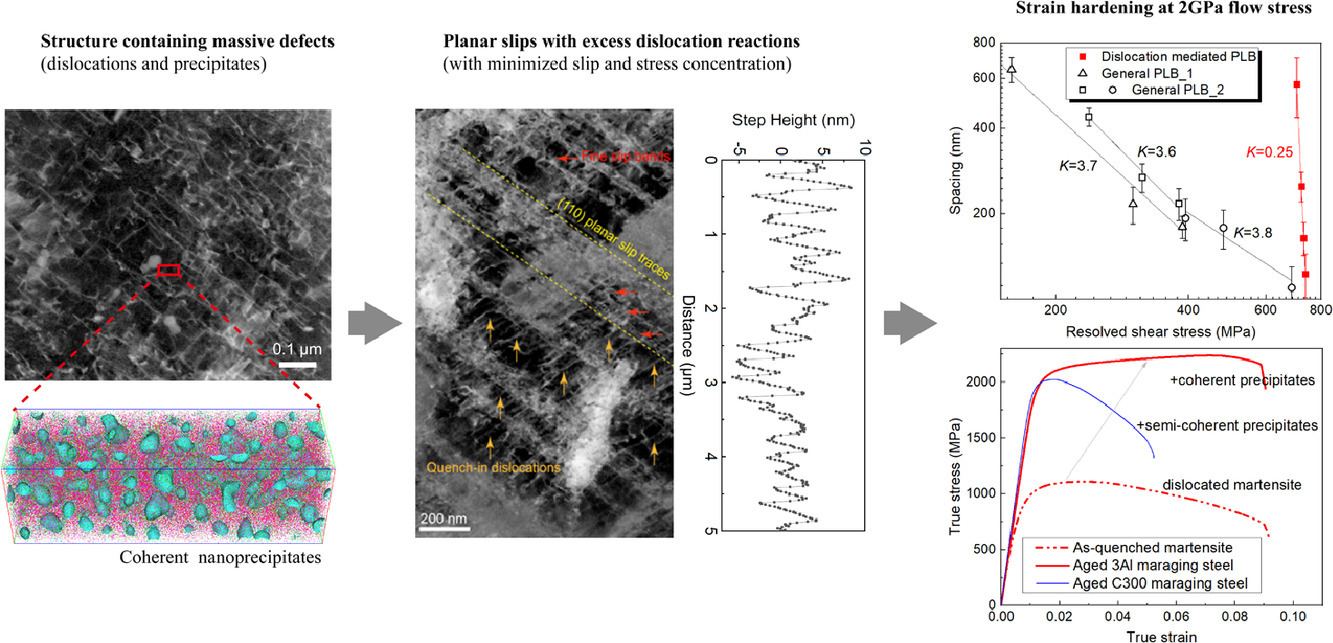

Vol. 213,1 Jul. 2021, 116984

9. Strain hardening mediated by coherent nanoprecipitates in ultrahigh-strength steels

共格纳米析出对超高强度钢应变硬化的影响

S. H. Jiang, X.Q. Xu, W. Li, B. Peng, Y. Wu, X.J. Liu, H. Wang✉, X.Z. Wang, Z.P. Lu✉

H. Wang:wanghui@ustb.edu.cn(北京科技大学)

Z.P. Lu:luzp@ustb.edu.cn, luzhaoping@163.com(北京科技大学)

https://doi.org/10.1016/j.actamat.2021.116984

摘要

通过位错或纳米析出达成材料强化往往会受到强塑性平衡的限制,这在强度超过2GPa的材料中尤为明显。本研究中,我们报道了一种通过调控不同晶格缺陷间的相互作用实现超高强度马氏体钢中持续应变硬化的机制。我们发现,快速析出的低错配的B2 Ni(Al, Fe)有序相可以有效地抑制淬火位错的回复。在塑性变形过程中,有序纳米相引起的高切削应力不仅可以使得大量位错在平面中移动,而且大幅增加了马氏体中位错的平均自由程。同时,位错的平面滑移使得这些位错与之前已经存在的位错之间产生大量位错反应,从而及时恢复因切割析出而减弱的局部切削应力。这种机制不仅减小了滑移集中和滑移带内的共面位错密度,而且促进了滑移带细化,使得材料能够实现2GPa的屈服强度和9%的断裂延伸率。这一研究表明,通过调控材料中不同类型晶格缺陷间的相互作用,可以同时提高材料的强度和延性。

ACTA

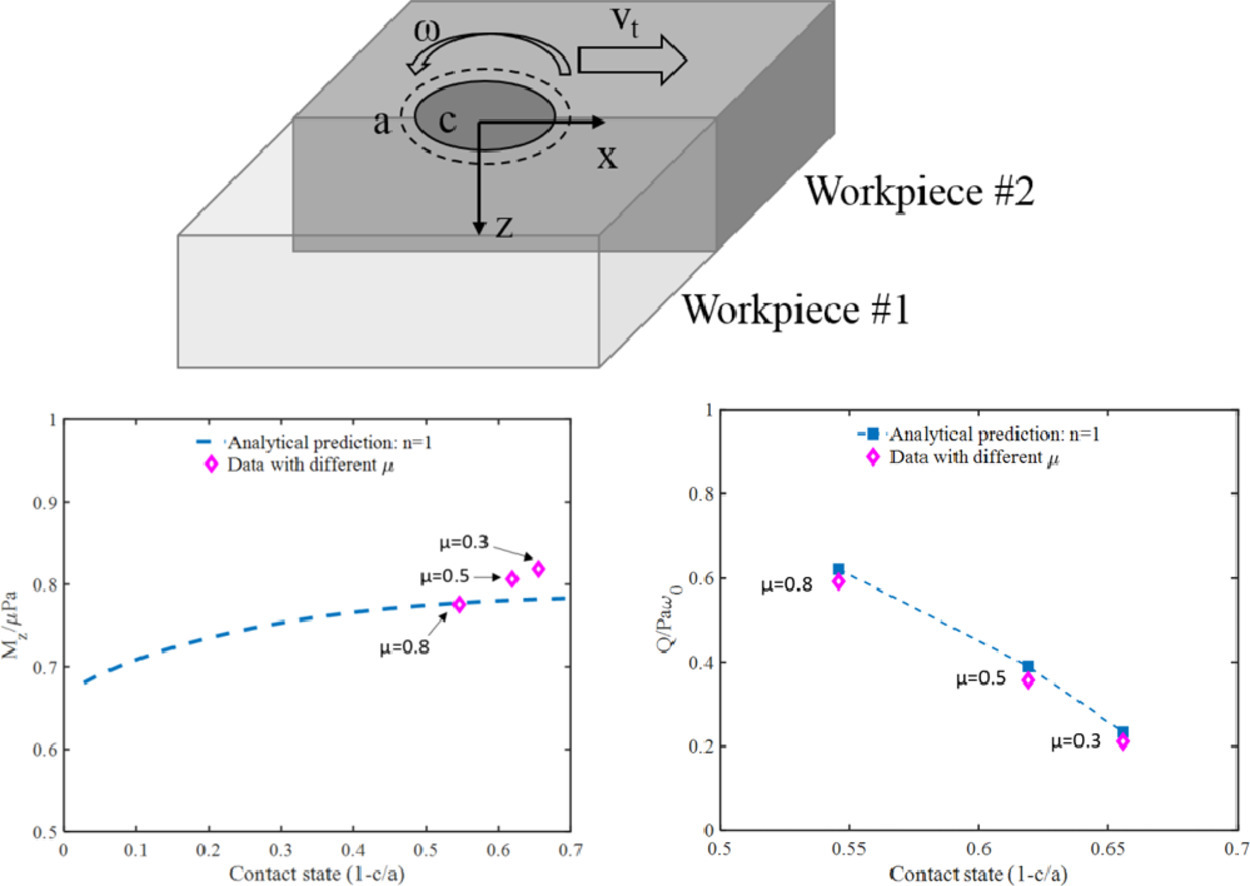

Vol. 213,1 Jul. 2021, 116969

10. Tool-workpiece stick-slip conditions and their effects on torque and heat generation rate in the friction stir welding

搅拌摩擦焊接过程中的工具-工件粘滑状态及其对扭矩和产热率的影响

Xue Wang, Yanfei Gao✉, Xun Liu, Martin McDonnell, Zhili Feng✉

Y. Gao:ygao7@utk.edu

Z. Feng:fengz@ornl.gov

https://doi.org/10.1016/j.actamat.2021.116969

摘要

搅拌摩擦焊接(FSW)在固态连接过程中不需要熔化,可在各种工况和材料中应用,在汽车和航空航天工业中应用尤其广泛。然而由于我们缺乏对工具-工件摩擦过程中材料组织演变和界面结合的深入理解,因此目前加工参数、材料性能、结合程度等之间的关系仍是经验性的。虽然一般认为,工具-工件间的粘着和滑动是影响扭矩和产热的主要因素,但界面场的定量测量却十分困难。另一方面,基于计算流体力学(CFD)的数值模拟强烈依赖于界面压力和剪切应力条件,只能通过中远距离的温度场来验证模拟预测,但温度场对界面摩擦行为不敏感。本文首先对两种基于CFD的模拟方法和基于有限元的欧拉拉格朗日耦合(CEL)模型,进行了比较,其中CEL模型采用库仑摩擦实现了粘着滑动的自发演化。之后,我们基于Hill-Bower相似关系建立了一个解析模型,模型解释了为何在稳态条件下粘着-滑动分数会保持不变,并将粘着-滑动分数与工艺参数建立了联系。我们进一步推导了转矩和产热率的无量纲函数,讨论了各种数值方法的优缺点。研究表明,我们的解析模型与数值模拟和文献实验结果吻合良好。以上结果对焊接过程中的临界应变速率和温度场分析具有重要意义。

ACTA

Vol. 213,1 Jul. 2021, 116924

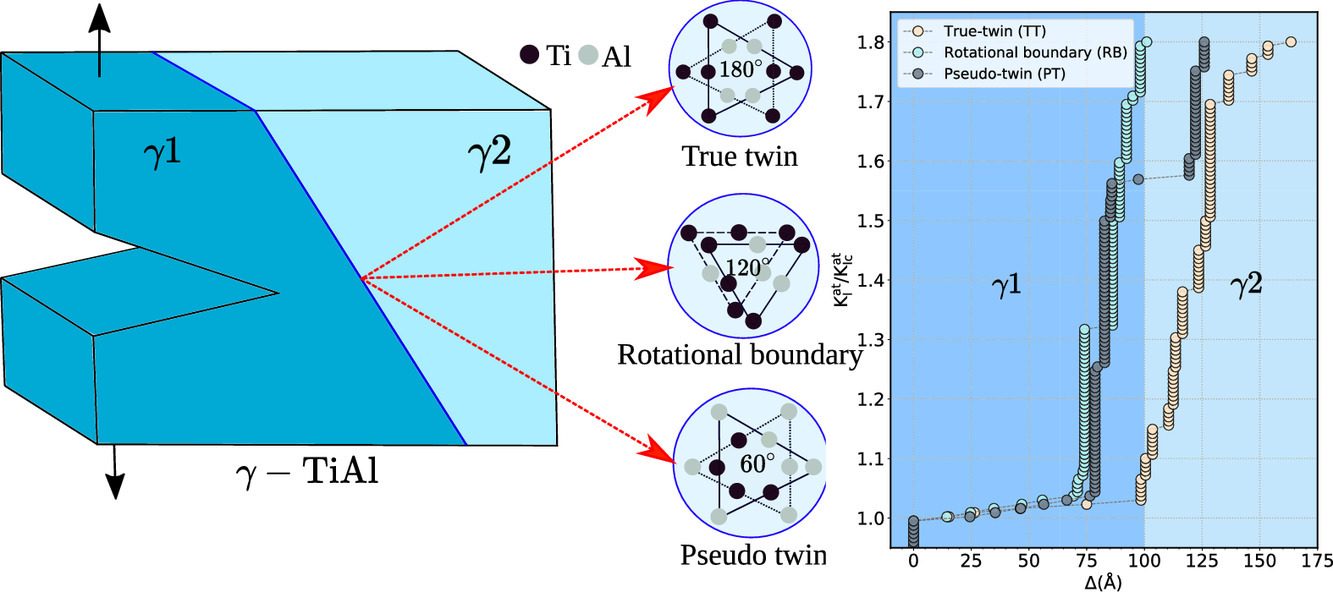

11. Twin-boundary assisted crack tip plasticity and toughening in lamellar γ-TiAl

孪晶界对层状γ-TiAl裂纹尖端塑性的影响及其增韧作用研究

Anupam Neogi✉, Rebecca Janisch✉

A. Neogi:anupam.neogi@rub.de

R. Janisch:rebecca.janisch@rub.de, rebecca.janisch@icams.ruhr-uni-bochum.de

https://doi.org/10.1016/j.actamat.2021.116924

摘要

层状γ -TiAl合金内部的孪晶界,包括真孪晶界(TT)、转动孪晶界(RB)和伪孪晶界(PT)都能够有效地强化组织。为设计具有优异力学性能的微观组织,我们需要深入理解界面对断裂行为的影响。为此,我们采用分子静力学模拟结合线弹性断裂力学分析,研究了不同孪晶界的局部晶格取向和原子结构对裂纹扩展的影响。研究表明,裂纹扩展方向对断裂韧性和层间裂纹的扩展机制有重要影响。例如,TT、RB和PT面的<11-2]方向裂纹尖端能够发射出大量位错,而沿相反方向的裂纹则是脆性的。而对于穿层裂纹,其尖端则表现出明显的韧性。在TT处,高应力条件写,脆性裂纹能够穿过界面传播至近邻的γ’ 相,而在RB和PT处,裂纹尖端发生钝化,引起位错发射和增韧。以上研究表明,改变界面的方向是调控层状TiAl塑性和韧性的有效手段。